Description

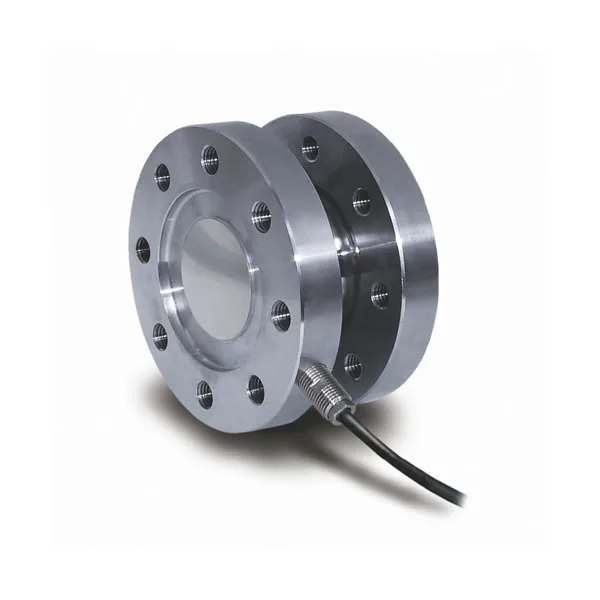

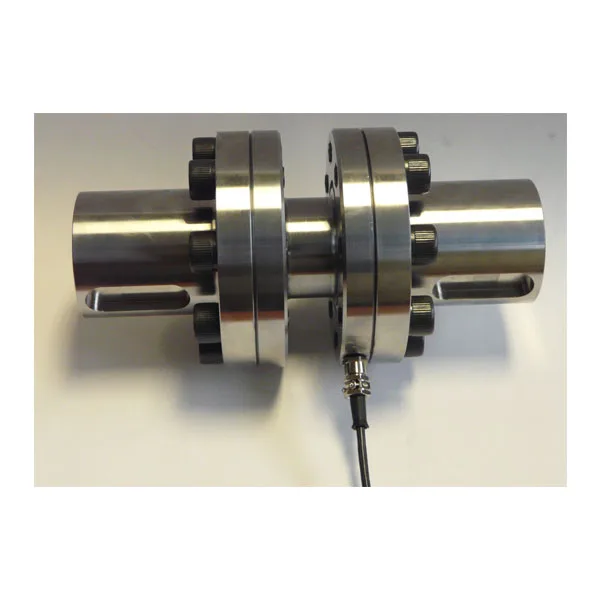

STATRIC torque transducers

For the measurement in clockwise and anticlockwise directionFLANGE process coupling

Nominal torque from 50 N•m to 5000 N•m

Class (EURAMET cg-14): 0.05 and 0.1

Linearity and Hysteresis: 0.03%

Output: 1 mV/V

HIGH ACCURACY

Dimensions[mm]

| CODE (Class 0,05) | CODE (Class 0,1) | TORQUE |

|---|---|---|

| MTRX50NM005 | MTRX50NM01 | 50 N·m |

| MTRX100NM005 | MTRX100NM01 | 100 N·m |

| CODE (Class 0,05) | CODE (Class 0,1) | TORQUE |

|---|---|---|

| MTRX200NM005 | MTRX200NM01 | 200 N·m |

| MTRX500NM005 | MTRX500NM01 | 500 N·m |

| MTRX1KNM005 | MTRX1KNM01 | 1 kN·m |

| MTRX2KNM005 | MTRX2KNM01 | 2 kN·m |

| CODE (Class 0,05) | CODE (Class 0,1) | TORQUE |

|---|---|---|

| (1) MTRX3KNM005 | (1) MTRX3KNM01 | 3 kN·m |

| (1) MTRX5KNM005 | (1) MTRX5KNM01 | 5 kN·m |

(1) ACCREDIA certification can NOT be performed by LAT n° 93 Laboratory, on request it can be ordered to other Accredited Laboratories.

Technical Data

| Accuracy class: EURAMET cg-14 | 0.05 | 0.1 |

| STATIC NOMINAL TORQUE | 50 – 100 N·m 200 – 500 N·m 1 – 2 – 3 – 5 kN·m |

|

| RELATIVE ERROR (at reading) a) repeatability 0°-120°-240° (b) b) interpolation (fa) c) hysteresis (h) d) zero (fo) |

≤ ±0.050%(1) ≤ ±0.025%(1) ≤ ±0.063%(1) ≤ ±0.012% F.S. |

≤ ±0.100%(1) ≤ ±0.050%(1) ≤ ±0.125%(1) ≤ ±0.025% F.S. |

| LINEARITY HYSTERESIS |

≤ ±0.03% F.S. ≤ ±0.03% F.S. |

|

| TEMPERATURE EFFECT (10°C) a) on zero b) on sensitivity |

≤ ±0.020% F.S. ≤ ±0.010% F.S. |

|

| NOMINAL SENSITIVITY SENSIVITY TOLERANCE |

1 mV/V ≤ ±0.1% F.S. |

|

| INPUT RESISTANCE OUTPUT RESISTANCE INSULATION RESISTANCE ZERO BALANCE RECOMMENDED SUPPLY VOLTAGE NOMINAL SUPPLY VOLTAGE RANGE MAXIMUM SUPPLY VOLTAGE |

700 ±2W 705 ±2W >5 GW ≤ ±0.5% F.S. 10 V 1-15 V 18 V |

|

| MECHANICAL LIMIT VALUES: a) service load b) max permissible load c) breaking load d) max transverse load e) max permissible dynamic load |

120% F.S. 150% F.S. >300% F.S. 50% F.S. 75% F.S. |

|

| REFERENCE TEMPERATURE T EMPERATURE NOMINAL RANGE SERVICE TEMPERATURE RANGE STORAGE TEMPERATURE RANGE |

+23°C 0/+60°C -10/+70°C -20/+80°C |

|

| PROTECTION CLASS (EN 60529) EXECUTION MATERIAL CABLE LENGTH |

IP67 Acciaio Inox / Stainless Steel 5 m |

|

| NOMINAL TORQUE [N·m] | 50 | 100 | 200 | 500 | 1k | 2k | 3k | 5k |

|---|---|---|---|---|---|---|---|---|

| WEIGHT | ~ 1.5 kg | ~ 3 kg | ~ 4.5 kg | |||||

| FIXING SCREWS a) diameter b) resistance class c) tightening torque |

M8 12.9 40 N·m |

M12 12.9 140 N·m |

M16 12.9 368 N·m |

|||||

| Max axial permissible load [kN] | 19 | 19 | 31 | 56 | 83 | 124 | 124 | 124 |

| Max lateral permissible load [kN] | 1.8 | 1.8 | 4 | 8 | 15 | 20 | 20 | 20 |

| Moment of inertia without considering screws and cables [g·m²] | 1.04 | 6.39 | 6.41 | 6.45 | 6.52 | 12.88 | 12.98 | |

(1) Percentual errors referred to reading, min. 1/10 of the nominal load.

For correct measurement both axial and transverse forces and bending moment should be absent.

In case of presence, they must not be greater than values indicated below, to be reduced in simultaneous presence of more solicitations.

Electrical Connections

PVC 80°C shielded cable, Ø 5.2mm with 6 tinned Ø 0.25mm2 conductors.

* Connected to the body of the torque transducer.

Reviews

There are no reviews yet.