Description

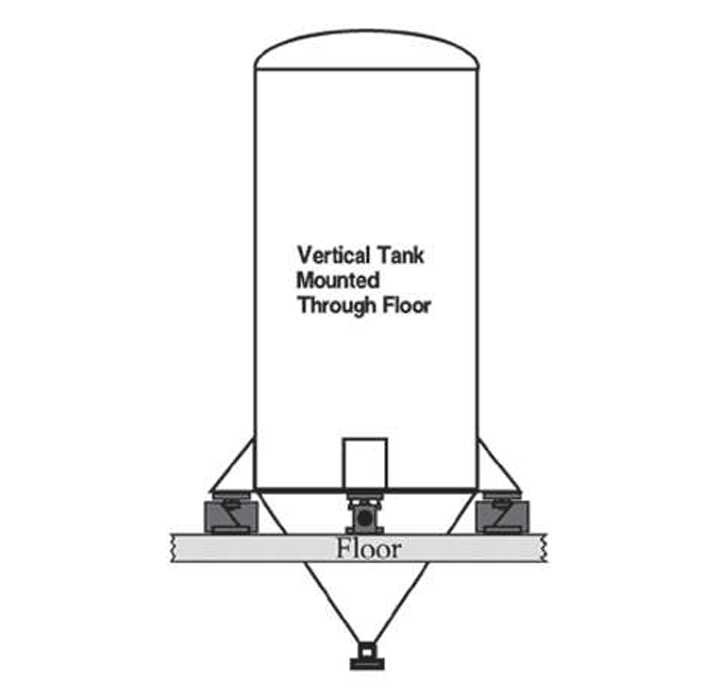

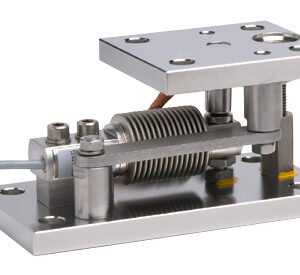

Z-BLOK Weigh Module

Features

Capacity range: 500, 1K, 2K, 5K, 10K, 20K, and 50K lb (227, 454, 907, 2.27K, 4.5K, 9K

and 22.7K kg)

‘Checkless’ design – no stay or check rods required

Low profile and integral thermal expansion assembly simplifies installation

Designed to meet ANSI/ASCE wind load and seismic requirements

Double cantilever design improves system performance and accuracy

cFMus approved

Application: Process Weighing & Batching,Hazardous Areas

Certificates: cFMus

Combined Error: 0.06-0.1 %

Environment Protection Class: IP67,IP66,IP65,IP54,IP20

Industry: Chemical,Pharmaceutical,Food & Beverage

Material: Plated Steel

Max Capacity: k lb: 25-115

Max Capacity: kN: 100-500

Max Capacity: ton: 10-50

Product Type: Weigh Modules & Load Cells

CONFIGURATION

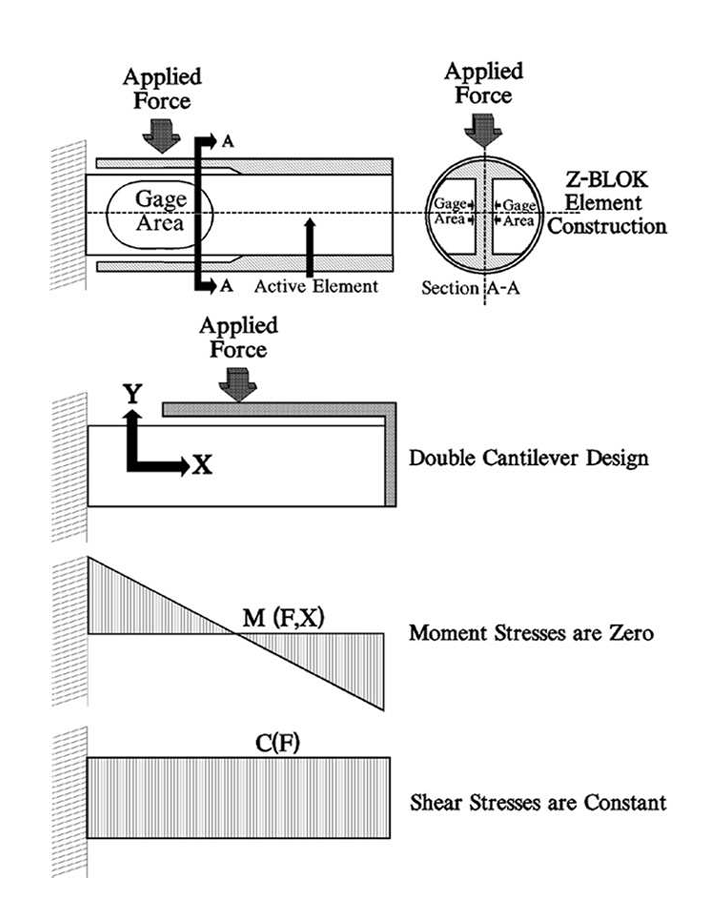

THE DOUBLE CANTILEVER ADVANTAGE

Double cantilever shear beams measure the shear component of force without errors caused by changing point or moment stresses. The Z-BLOK Weigh Module incorporates an outer sleeve that can be thought of as a second cantilever, rigidly attached to the free end of the irst cantilever. Thus the term double cantilever. With this design, rather than applying force at the free end of the beam, the point of load application is brought back to a point directly over the gaged area. The result is that bending moment is close to zero across the gaged area. Because a shear beam is designed to measure shear, not bending, any reduction in bending moment stress is desirable. The second cantilever also is effective at isolating load application point stresses from the active element. Reducing the force due to bending moment in a cantilever beam has a side beneit—a reduction in the beam’s strength requirements. By reducing the bending moment induced at the weakest part of the shear beam (section A-A), a double cantilever shear beam can be operated at a stress level well below that of a single cantilever shear beam. The result is a more conservative structural design with high overload capacity and fatigue resistance. Double cantilever shear beams approach the ideal in load cell design; they measure the desired force while ignoring any extraneous forces that may be present.

Double cantilever shear beams measure the shear component of force without errors caused by changing point or moment stresses. The Z-BLOK Weigh Module incorporates an outer sleeve that can be thought of as a second cantilever, rigidly attached to the free end of the irst cantilever. Thus the term double cantilever. With this design, rather than applying force at the free end of the beam, the point of load application is brought back to a point directly over the gaged area. The result is that bending moment is close to zero across the gaged area. Because a shear beam is designed to measure shear, not bending, any reduction in bending moment stress is desirable. The second cantilever also is effective at isolating load application point stresses from the active element. Reducing the force due to bending moment in a cantilever beam has a side beneit—a reduction in the beam’s strength requirements. By reducing the bending moment induced at the weakest part of the shear beam (section A-A), a double cantilever shear beam can be operated at a stress level well below that of a single cantilever shear beam. The result is a more conservative structural design with high overload capacity and fatigue resistance. Double cantilever shear beams approach the ideal in load cell design; they measure the desired force while ignoring any extraneous forces that may be present.

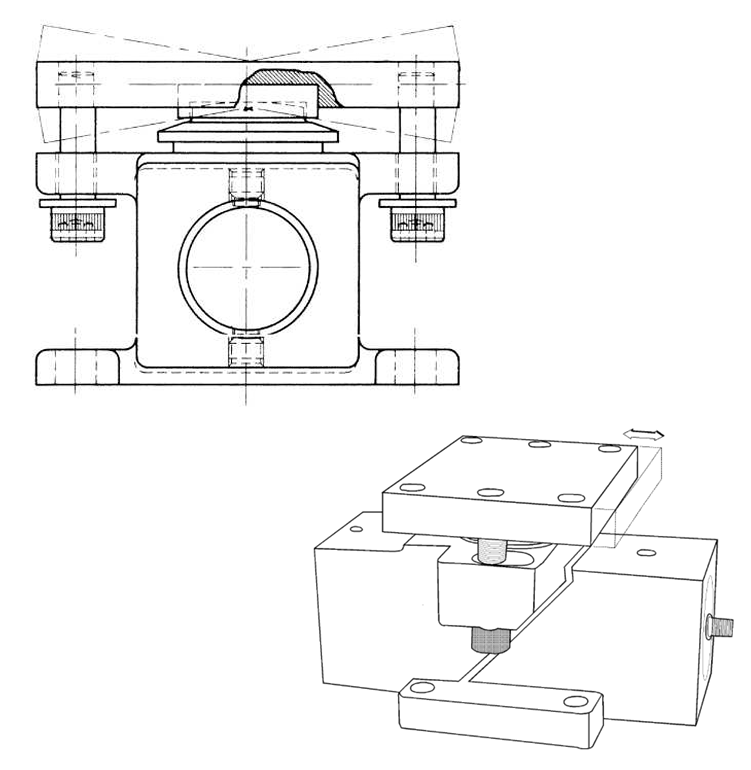

THE INTEGRAL THERMAL EXPANSION/RETAINER PLATE ADVANTAGE

Z-BLOK’s unique design incorporates an integral expansion/retainer plate assembly with retainer bolts. This mounting arrangement provides simple checkless installation while allowing for minor mounting surface irregularities and vessel/structure expansion and contraction. The spherical load button and socket eliminates torsional stresses on the load element caused by non-level or out of plumb mounting surfaces. End load stresses, caused by vessel/structure expansion and contraction or process vibration, are negated by the telon impregnated slide plate. The expansion/retainer plate assembly is attached to the module at the factory and requires no adjustments. The high strength bolts that connect the module and expansion/retainer plate assembly provide resistance to uplift forces and complete the checkless design.

Load Cell Weigh Module]

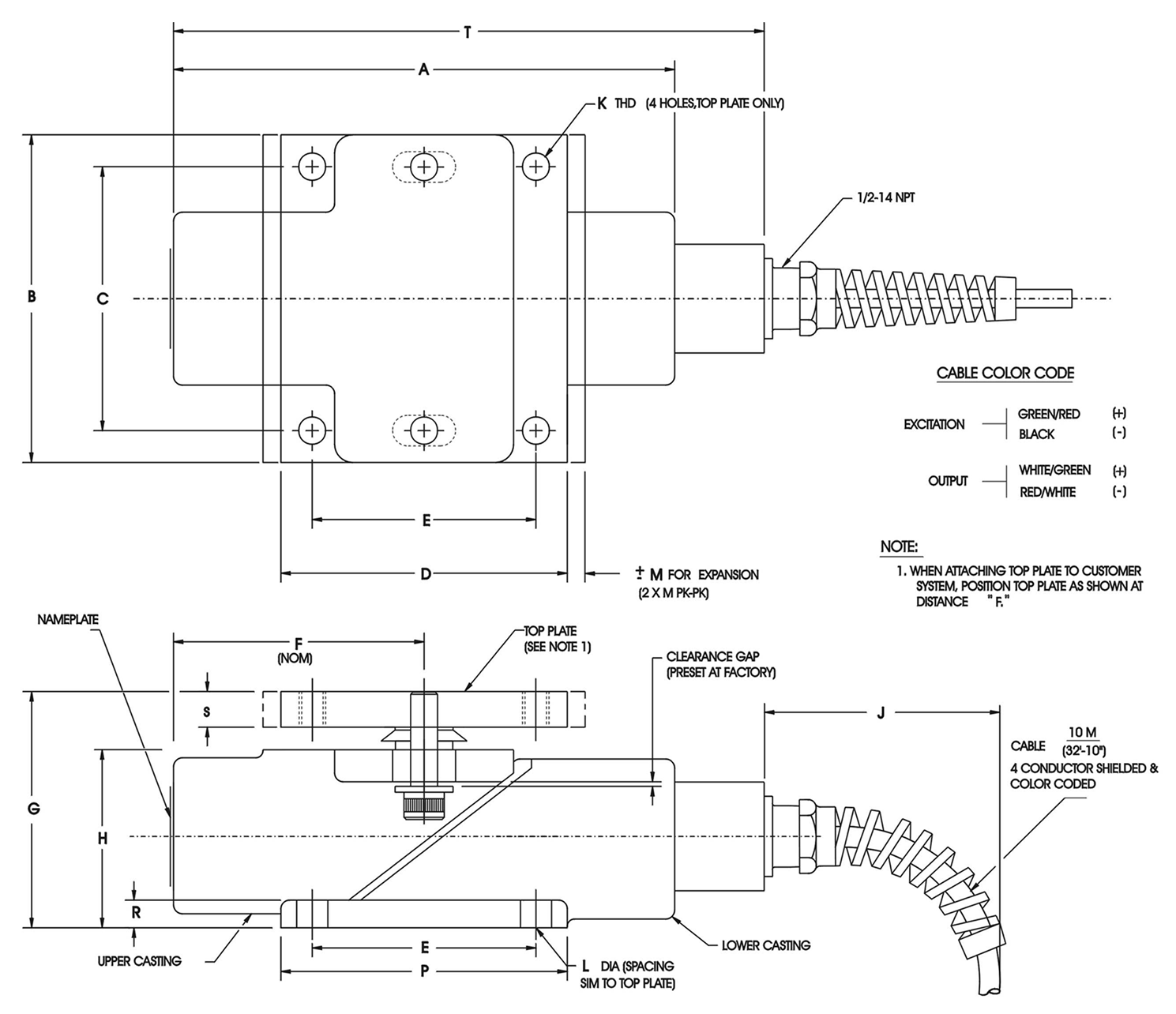

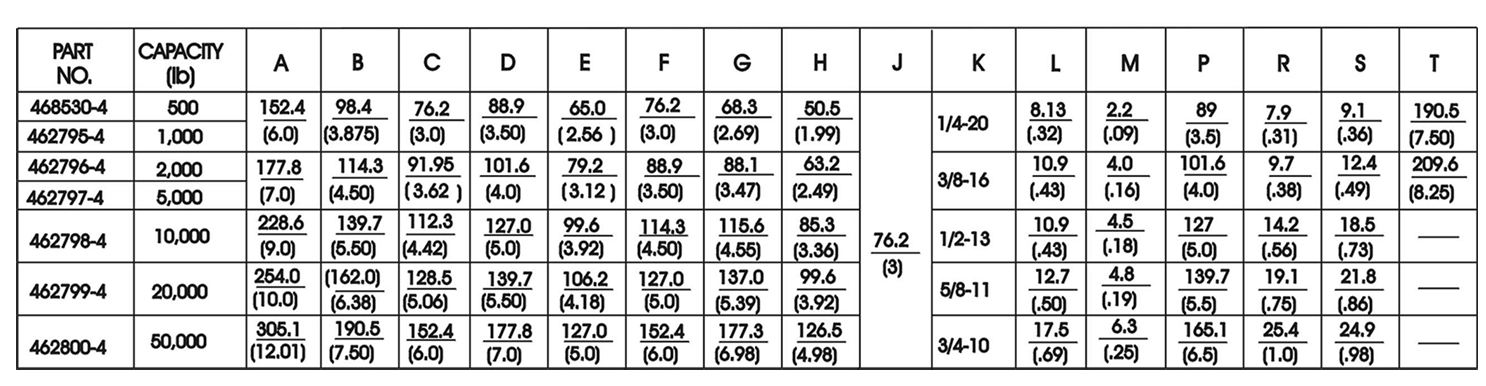

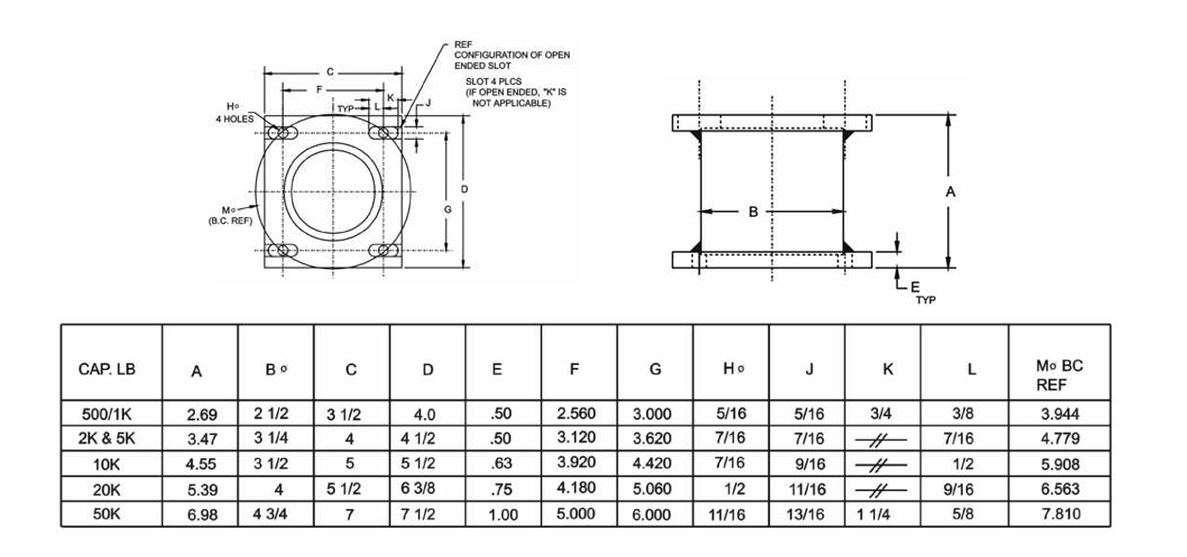

OUTLINE DIMENSIONS

Dimensions shown in mm (inches)

SIMULATED WEIGH MODULES

Thermal Insulation Pads In applications where heat conduction is a concern, BLH Nobel can provide thermal pads to isolate the Z-BLOK modules from the hot vessel. The one inch thick, phenolic glass pads install directly between the Z-BLOK expansion/retainer plate and the vessel gusset/mounting bracket for thermal insulation.

SPECIFICATIONS

| Category | Parameter | Value |

|---|---|---|

| PERFORMANCE | Capacity | 500, 1K, 2K, 5K, 10K, 20K, 50K lb (227, 454, 907, 2.27K, 4.5K, 9K, 22.7K kg) |

| Rated Output (RO) | 2.0 mV/V ±0.1% | |

| Repeatability | 0.01% RO | |

| Combined Error (best fit) | 0.10% RO | |

| Zero Balance | 5% RO | |

| Creep (20 minutes) | 0.03% RO | |

| Temperature Effect on Zero | 0.0017% RO / °F | |

| Temperature Effect on Span | 0.0020% Load / °F | |

| ELECTRICAL | Recommended Excitation | 10 VDC (15 VDC max.) |

| Input Resistance | 350 Ω ±3 Ω | |

| Output Resistance | 350 Ω ±3 Ω | |

| Cable Length | 32 ft 10 in cable with conduit fitting | |

| TEMPERATURE | Safe Range | –40 to 220 °F |

| Compensated Range | +30 to 130 °F | |

| ADVERSE LOAD RATINGS | Safe Load | 150% rated capacity |

| Safe Sideload | 100% rated capacity | |

| Safe Uplift | 50% rated capacity | |

| MATERIAL | Beams | 15-5PH Stainless Steel |

| Brackets | Polished zinc chromate | |

| DEFLECTION & WEIGHT | 500 lb | Deflection: 0.012 in / Weight: 10 lb |

| 1K lb | Deflection: 0.012 in / Weight: 10 lb | |

| 2K lb | Deflection: 0.013 in / Weight: 15 lb | |

| 5K lb | Deflection: 0.027 in / Weight: 15 lb | |

| 10K lb | Deflection: 0.023 in / Weight: 35 lb | |

| 20K lb | Deflection: 0.047 in / Weight: 50 lb | |

| 50K lb | Deflection: 0.066 in / Weight: 75 lb |

BLH Nobel is continually seeking to improve product quality and performance. Speciications may change accordingly.

Reviews

There are no reviews yet.