Description

DISOMAT® Tersus Weighing Terminal

APPLICATION

The compact DISOMAT Tersus weighing terminal is ideal for a wide range of weighing applications, whether for operating scales, processing data, controlling processes, or communicating with customer systems.

The system includes four predefined configurations for typical applications, which can be easily selected:Cargo scales

- Crane scales

- Filling scales

- Discharge scales

These function variants provide a proven range of functions tailored to each application, with the possibility to adapt the weighing terminal to specific scale requirements.

An optional configuration for use as a road weighbridge (in/out scale) is also available.

The functionality of the DISOMAT Tersus can be adapted to almost any weighing task by configuring the links between logical function blocks. This can be done either using the DISOPLAN PC software (graphical interface) or directly on the terminal, allowing easy and cost-effective local adaptation without extensive programming.

In the optional two-channel measuring version, the DISOMAT Tersus can be used for:

- Twin-unit road weighbridges

- Two-trolley cranes with separate overload monitoring

- Simultaneous monitoring of two silo/bin levels

- Two parallel feeding processes at the same time

EQUIPMENT

The backlit, graphics-compatible QVGA display (320 × 240 dots) continuously shows the weight, even while operators are entering data in the seven-line dialogue area or when status information is displayed.

Displayed information may include:

- Feeding process status (bar graph)

- Input/output status

- Operator guidance and help messages

A special input mode (“telephone alphabet”) allows entry of alphanumeric characters via keyboard.

An optional remote alphanumeric keyboard is also available for more convenient data entry, especially for frequent text input.

A second independent control terminal can be added at any time using another DISOMAT Tersus in mirror configuration.

For control applications, the system provides:

- Up to 8 binary inputs

- Up to 12 binary outputs

- Optional analog I/O module (2 inputs / 2 outputs)

INTERFACES & EXPANDABILITY

You can adapt the functionality of the inputs and outputs to suit application requirements by flexibly linking function blocks.

The number of binary inputs and outputs can be expanded at any time using upgrade modules.

Three serial interfaces allow connection of peripheral devices such as printers and remote displays, as well as communication with data processing systems or PLCs.

An additional serial interface can also be retrofitted if required.

Retrofittable coupling modules are available for the most common industrial fieldbus systems (PROFIBUS, DeviceNet).

An Ethernet interface (100 MBaud) is included as standard equipment.

DISOMAT Tersus features four built-in USB ports for connecting:

- External keyboard

- Legal-for-trade memory

- Printer

MEASURING PERFORMANCE

The DISOMAT Tersus measuring system offers extremely high resolution and outstanding measuring speed, providing large performance reserves even for demanding applications such as:

- Scales with low load cell utilization

- Scales with load sensors installed in hazardous areas

- Fast filling processes

The terminal also performs reliably under extreme temperature conditions, with an operating range of –30 °C to +60 °C.

DATA SECURITY & MAINTENANCE

All scale parameters, including calibration data, are stored in the connector plug (dongle) of the load cell cable.

In the event of a fault, any component can be replaced without recalibration or re-verification. The system immediately resumes operation within legal-for-trade specifications.

(This also applies independently to both channels in the two-channel version.)

The modular system design minimizes downtime and reduces maintenance costs.

HOUSING VERSIONS

- Desk-top unit

- Panel mount unit

- Stainless steel unit

- Field unit

- 19″ mounting rack

These versions provide suitable solutions for virtually all operating environments.

OPERATION & SETTINGS

Standard operating languages are German and English.

Additional languages can be easily loaded using the PC-based DISOPLAN configuration software (Windows application).

Currently available languages include:

- Italian

- Spanish

- French

- Polish

- Czech

- Hungarian

- Russian

DISOPLAN also allows you to:

- Graphically configure function blocks

- Set all device parameters

- Calibrate the scale

- Easily format print layouts

- Record weight curves

- Read out full terminal configuration (backup)

- Restore data to a replacement terminal

DISOPLAN communicates with DISOMAT Tersus via:

- Serial interface

- Ethernet

- Bluetooth (optional)

All parameters and calibration data are stored safely within the terminal and protected against power failure.

The internal real-time clock continues to operate for at least seven days without power.

PRINTING FUNCTIONS

Flexible print formatting allows free layout of weighing reports.

Print vouchers can be graphically designed directly in DISOPLAN with preview.

You can print the following together with weight data:

- Date and time

- Serial number

- Totalized weights

- Number of weighings

- Up to 5 free text fields (max. 25 characters each)

- 3 stored texts (26 characters each)

The print layout is defined via formats, and up to six different print formats can be stored.

They offer the right packaging for virtually every environment.

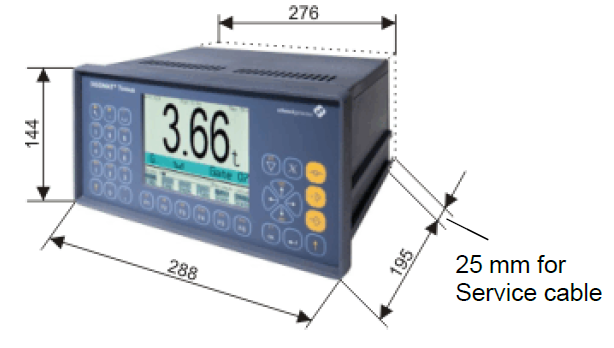

The available housing designs for DISOMAT Tersus

VTG 20450 desk-top unit |

VEG 20450 panel mount unit |

|---|---|

|

|

VFG 20450 crane/field unit |

VKG 20450 stainless steel unit |

Technical Data

| Display | Colour-LCD, 240 x 320 pixels,

120 mm x 90 mm Weight display 22 mm digit height, 1 Status line and 7 dialog lines per 5 mm digit height |

| Keyboard | Membrane keyboard with 33 multiple-

function keys, 12 of which are configura- ble function keys |

| Supply voltage | 85 – 250 VAC, 47 – 63 Hz

24 VDC (18 – 36 VDC) |

| Power consumption | max. 20 VA |

| Temperature range | Service temperature: -30 °C to +60 °C Verifiable. -30 °C to +40 °C

Storage temperature: -40 °C to +60 °C |

| Electro-magnetic

environment |

E2 (OIML D11) |

| Input Signal | 0 – 35 mV |

| Sensitivity | 0.4 μV/d |

| Measuring rate | 132 measurements/second |

| Increment Value | 1, 2 and 5 etc. adjustable from

0.01 – 5,000 |

| Unit | kg, g, t, lb, N, kN |

| Number of Compo- nents | Legal-for-trade operation: max. 8,000 d Multi-range scale 3 x 4,000 d

Multi-interval scale 3 x 4,000 d No limits to resolution in non legal-for- trade operation |

| Taring | To 100 % of the weighing range |

| Zero setting equipment | Can be set to a max. 20 %

Automatic zero point lag 0.5 d/s, can be switched off |

| Filter | Mains-synchronous noise-signal sup- pression Interference signals ≥100 dB , Common mode rejection ≥110 dB

Software filter, filter interval 0 – 10 s |

| Linearity error | <0.025 ‰ |

| Zero point stability, TK0 | <0.4 μV / 10 K

corresponds to 0,012 ‰ / 10 K |

| Range stability, TKc | <0.03 ‰ / 10 K |

| Accuracy, Fcomb | <0.05 ‰ / 10 K |

| Date/Time | Real-time clock,

Back-up time at least 7 days |

| Load cell impedance | At least 43 Ω (corresponds to 8 x 350 Ω – load cell or >20 RT load cells à 4,000 Ω) also valid as minimum total impedance for two-channel terminals

(such as 2 x 4 x 350 Ω) |

| Load cell supply | 12 V alternating current supply |

| Binary Inputs | 8 inputs, indirect coupled, securely iso- lated, 18 – 36 VDC

Auxiliary 24 V supply available for con- trolling the inputs (max. 150 mA) |

| Binary outputs | 12 outputs, indirectly coupled, securely isolated (relay), passive. Load capacity 24 VDC/VAC max. 500 mA,

90 – 250 VAC max. 300 mA. The refresh rate of the outputs in the ‘fast comparator’ function is 132 x per second |

| Serial interfaces | 3 interfaces for a printer, data processing or secondary display S1 and S2 can be changed to

– RS232 – RS422/485-4-wire – RS485-2-wire – The change can be made using software (no jumpers) S3: RS232 fixed, using Bluetooth as an option – Max. baud rate for all interfaces: 38,400 Baud |

| Data processing procedures | Siemens 3964R S5 (RK512)

Modbus Standard Schenck DDP 8672 procedure Schenck DDP 8785 poll procedure |

| Secondary dis- play procedures | DTA

DDP 8861 DDP 8850 |

| Ethernet | 10/100BASE-T, full duplex-compatible |

| USB ports | 4 x USB 2.0 host (master) |

Options

| Second measurement

input |

e.g. for twin-unit scales |

| Remote VTT 28000 PC

swivel keyboard (USB) |

|

| Data input via

Barcode scanner |

On request |

| Verifiable VMM 20450 data memory for weigh

data as a substitute for check printer |

Memory capacity 256 MB for typically 3 m. weighing operations |

| VEA 20451

expansion card |

2 outputs, 0(4) – 20 mA, load max. 500 Ω Resolution: 10,000 parts Refresh rate: 10/s

2 inputs 0(4) – 20 mA or 0 – 10 V Linearity <0.15 ‰ Zero-point stability <0.25 ‰ / 10 K Stable range <0.25 ‰ / 10 K In addition: two binary outputs open collector 24 VDC, galvanically free, max. 200 A |

| Modbus-RTU

fieldbus card |

1 serial interface |

| PROFIBUS fieldbus card | PROFIBUS DP and DP-V1 protocol |

| PROFINET fieldbus card | PROFINET IO protocol |

| DeviceNet fieldbus card | |

| Bluetooth (serial inter-

face S3) |

Class 1 or 2 module, maximum

transmission link 100 (15) m |

| Radio

Data transmission |

For printing data or data processing

connection |

| I/O extension | – Binary inputs/outputs (max. addi- tional 16 inputs or 16 outputs)

– Added analog output |

The matching safety barrier assemblies for connecting intrinsically safe weighing platforms and operating units in the ATEX 2G category (zone 1)

Other options or customised functions for your applications at reques

Reviews

There are no reviews yet.