Description

Bending beam load cell LC Nito PR 77 and mounting kit PR 97

For weighing process vessels and use in belt and platform scales

The deflecting beam load cells of the LC Nito series have been specially designed for weighing process vessels and use in belt and platform scales. The mounting kit PR 97 ensures that movements of the vessel and/or the supporting construction have a negligible effect on the weighing result.

Verifiable load cells for a variety of industrial applications

- The load cells guarantee highly accurate weighing results. All load cells are verifiable according to OIML and NTEP.

- A comprehensive optional portfolio of transmitters, indicators and controllers ensures reliable continuous processing of the measurement signals as desired.

- The hermetically sealed load cell LC Nito has a protection class of IP68, so it provides highly accurate results even under the harshest ambient conditions.

- The hermetically sealed load cell LC Nito has a protection class of IP68, so it provides highly accurate results even under the harshest ambient conditions.

| Bending beam load cell LC Nito | |||||

| Parameters | Description | Abbr. | PR 77 C3MR | PR 77 C6 | Unit |

| Accuracy class | 0.02 | 0.012 | % Emax | ||

| Minimum dead load | Lowest limit of specified measuring range | Emin | 0 | % Emax | |

| Maximum capacity | Highest limit of specified measuring range | Emax | 10, 20, 50, 100, 200, 250, 500 | 50, 100, 200 | |

| Maximum usable load | Upper limit for measurements | Elim | 150 | % Emax | |

| Destructive load | Danger of mechanical destruction | Ed | 300 | % Emax | |

| Minimum LC verification | Minimum load cell verification interval, vmin = Emax/Y | Y | 12,000 | 15,000 | |

| Deadload output return | Factor for deadload output return after load (DR = 1/2*Emax /Z) | Z | 3,000 | 6,000 | |

| Rated output | Relative output at maximum capacity | Cn | 2 | mV/V | |

| Tolerance on rated output | Permissible deviation from rated output | dc | ± 0.07 | %Cn | |

| Zero output signal | Load cell output signal under unloaded condition | Smin | 0 ± 1 | %Cn | |

| Repeatability error | Max. change in load cell output for repeated loading | R | < 0.01 | <0.0083 | %Cn |

| Creep | Max. change of output signal at Emax during 30 min. | dcr | < 0.0166 | <0.0083 | %Cn |

| Non-linearity1) | Deviation from best straight line through zero | dLin | < 0.0166 | <0.0116 | %Cn |

| Hysteresis1) | Max. difference in LC output between loading and unloading | dhy | < 0.0166 | <0.0083 | % Cn |

| Temperature effect (TK) on Smin | Max. change related to Cn of Smin per 10K in BT | TKSmin | < 0.0117 | <0.0093 | % Cn/10K |

| Temperature effect (TK) on parameter1) | Max. change related to Cn of C per 10K in BT | TKC | < 0.0117 | <0.0058 | % Cn/10K |

| Input impedance | Between supply terminals | RLC | 415 ± 65 | Ω | |

| Output impedance | Between measuring terminals | RO | 406 ± 0.35 | Ω | |

| Insulation impedance | Between measuring circuit and housing at UDC = 100 V | RIS | > 5,000 × 106 | Ω | |

| Nominal supply voltage range | To hold the specified performance | Bu | ≤ 12 | VDC | |

| Max. supply voltage | Continuous operation without damage | Umax | 15 | VDC | |

| Nominal ambient temp. range | To hold the specified performance | BT | -10…+40 | °C | |

| Usable ambient temp. range | Continuous operation without damage | BTu | -40…+80 | °C | |

| Storage temperature range | Without electrical and mechanical stress | BTi | -40…+80 | °C | |

| Barometric pressure influence | Influence of barometric pressure on output | < 0.007 | % Cn/kPa | ||

| Nominal deflection | Max. elastic deformation under maximum capacity | Snom | < 0.5 | mm | |

| Material | Stainless Steel | ||||

| Cable length | 3 | m | |||

| IP protection class | According to EN 60529 | IP66 / IP68 | |||

1) Non-linearity (dLin), hysteresis (dhy) and parameter temperature effect (TKC) are typical values. For OIML R60- and NTEP-approved load cells, the total of these values is within the permitted cumulative error limits.

| Accuracy classes and minimum verification interval, vmin | |||||||||

| Maximum capacity | Divisions nmax | Minimum LC verification, vmin | |||||||

| 10 kg | 20 kg | 50 kg | 100 kg | 200 kg | 250 kg | 500 kg | Unit | ||

| OIML | 3,000 | 0.83 | 1.67 | 4.17 | 8.33 | 16.67 | 20.83 | 41.67 | g |

| OIML | 6,000 | – | – | 3.3 | 6.7 | 13.3 | – | – | g |

| NTEP Class III Single/Multiple | 5,000 | 0.83 | 1.67 | 4.17 | 8.33 | 16.67 | 20.83 | 41.67 | g |

| NTEP Class III L Multiple | 10,000 | 0.30 | 0.58 | 1.4 | 2.8 | 5.6 | 6.9 | 13.9 | g |

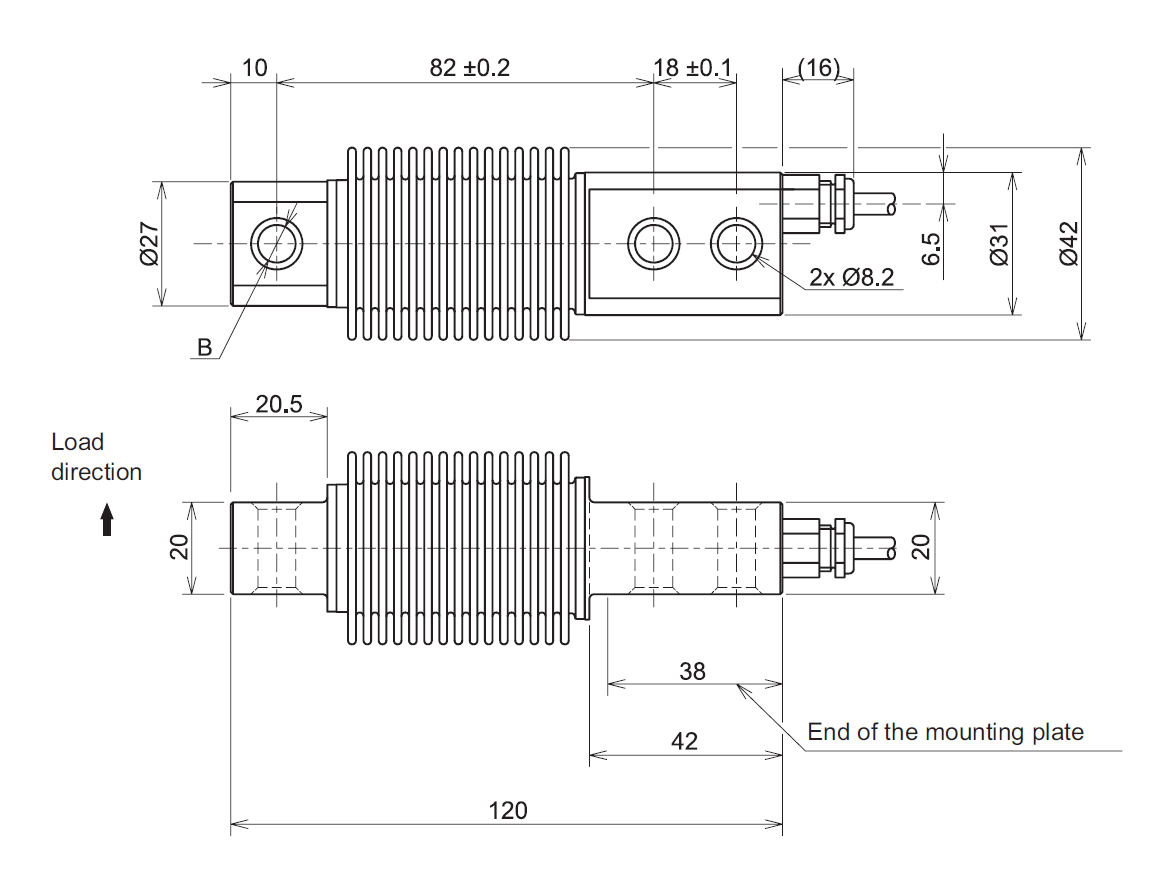

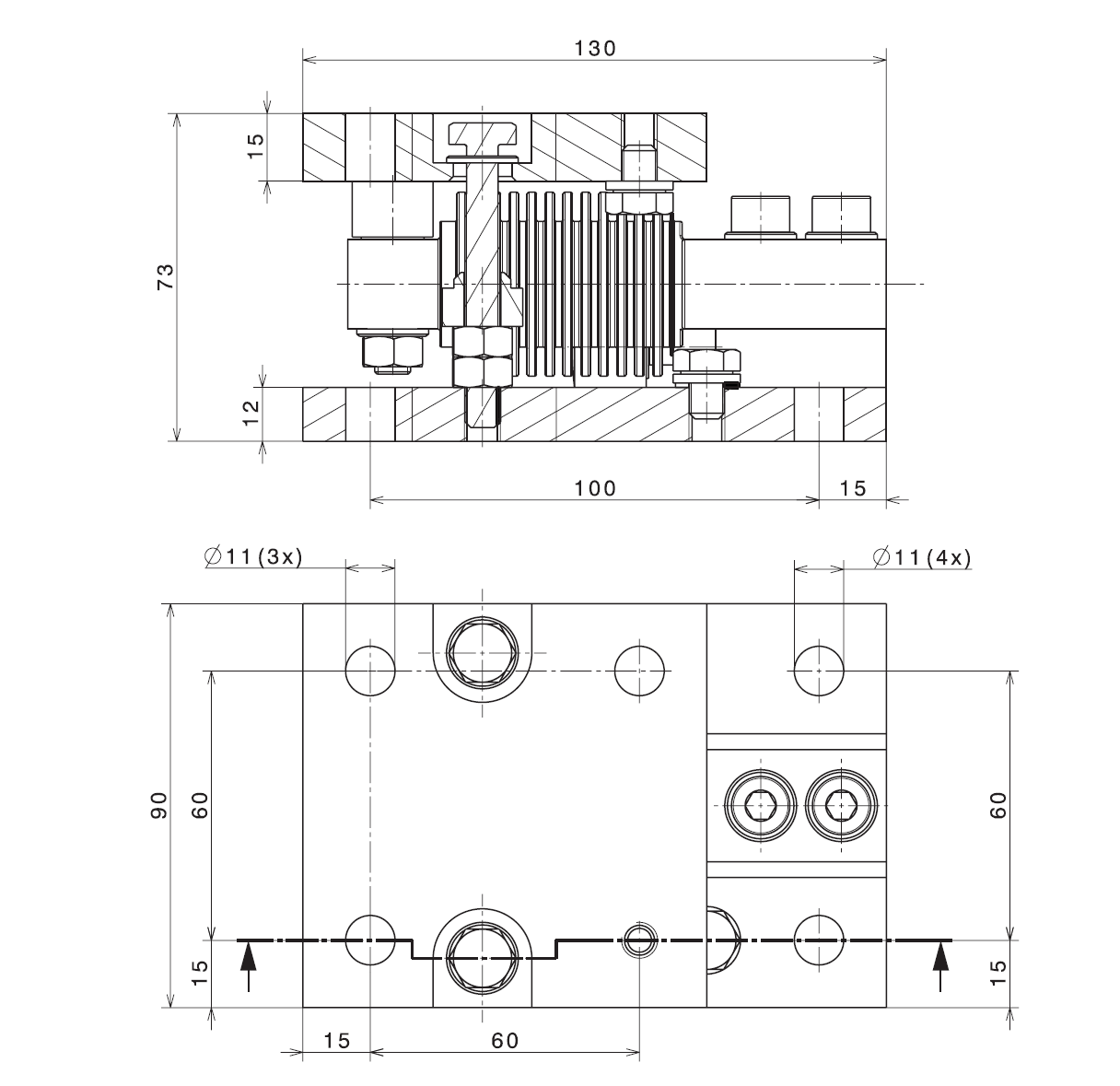

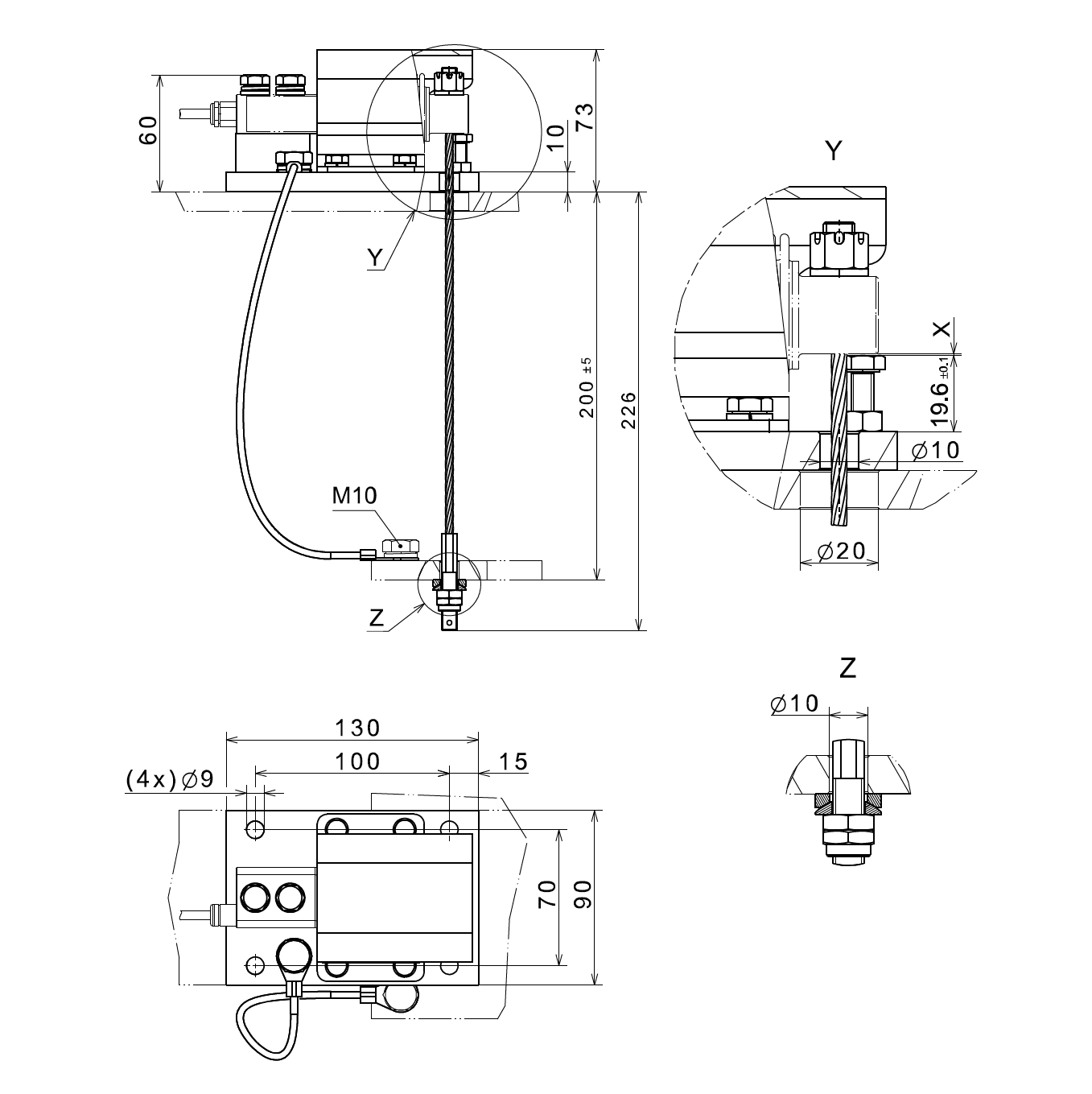

Technical diagrams

Bending beam load cell LC Nito

Mounting kit PR 97

| B | |

| 10 – 250 kg | 8.2 |

| 500 kg | 10.5 |

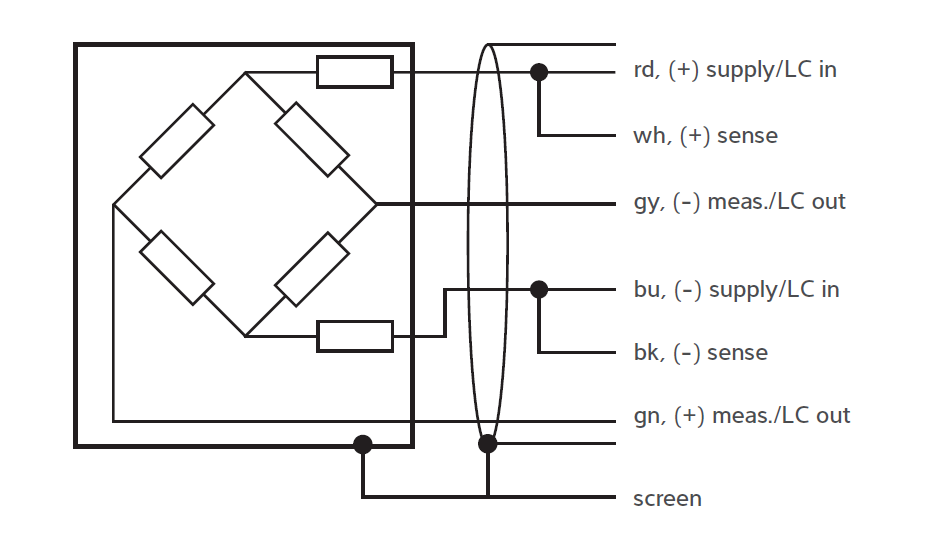

Circuit diagram

Ex approval

Scope of validity: Bending beam load cell LC Nito PR 77

| Bending beam load cell LC Nito PR 77 certificates | |||

| Zone | Marking | Certificate number | For |

| 0 and 1 | II 1G Ex ia IIC T6/T4 Ga | BVS 21 ATEX E 023 X IECEx BVS 21.0024X | Only PR 7x/xx E |

| 20 | II 1D Ex ia IIIC T₂₀₀ 165°C Da | ||

| 2 | II 3G Ex ec IIC T6/T4 Gc | All PR 7x without E | |

| 21 | II 2D Ex tb IIIC T110°C Db | ||

Ordering information

| Bending beam load cell LC Nito (PR 77) | |

| Typ | Order number |

| PR 77/10 kg C3MR | 9409 277 07010 |

| PR 77/20 kg C3MR | 9409 277 07020 |

| PR 77/50 kg C3MR | 9409 277 07050 |

| PR 77/100 kg C3MR | 9409 277 07110 |

| PR 77/200 kg C3MR | 9409 277 07120 |

| PR 77/250 kg C3MR | 9409 277 07125 |

| PR 77/500 kg C3MR | 9409 277 07150 |

| PR 77/50 kg C6 | 9409 277 06050 |

| PR 77/100 kg C6 | 9409 277 06110 |

| PR 77/200 kg C6 | 9409 277 06120 |

| PR 77/xxx kg C3MRE | 9409 677 07xxx |

| PR 77/xxx kg C6 | 9409 677 06xxx |

| Load cell accessories bending beam load cell LC Nito | ||

| Typ | Description | Order number |

| PR 97/00 N | MiniFLEX mounting kit for PR 77 up to 250 kg | 9405 300 97001 |

| PR 97/01 N | MiniFLEX mounting kit for PR 77 500 kg | 9405 300 97011 |

| PR 6007/00N | Mounting kit for PR 77 250 kg | 9405 360 07001 |

| PR 6007/00S | Mounting kit for PR 77 250 kg, stainless steel | 9405 360 07002 |

Reviews

There are no reviews yet.