Description

Torque measurement accurate + interference-free DRFN

The transducer is suited for the most varied measurement duties on threaded fasteners, to check and adjust assembly tools, like screwdrivers and spanners, and to sense loosening torques, etc. It can also be deployed in blocked mode to test torque wrenches. The device is powered wirelessly and the electrical output is wireless, as well. Hence, there is practically no wear on the device.

This sensor is suited for cyclical as well as continuous testing of tools. As the sensor is designed to be torsionally rigid any errors due to it are minimized.

Features

No service needed because of contactless data aquisition

High interference immunity due to amplified active signal

High accuracy due to frequency modulation and strain gage technology

Power supply

Optional angle detection

Technical specifications

| Measurement range | see above or datasheet |

| Supply voltage | 12 V DC ± 10% |

| Power consumption | < 200 mA |

| Rise time 10 – 90 % | 1 ms (1 kHz) |

| Voltage output | 0 – ± 5 V |

| Internal resistance | 100 Ω |

| Ripple | < 100 mVss |

| Nonlinearity | < 0,15 % |

| Hysteresis | < 0,1% |

| Deviation at zero point | ≤± 100 mV |

| Operating temperature | 0 – 60 °C |

| Compensated temperature range | 5 – 45 °C |

| Temperature error zero point sensitivity |

0,01 % / K 0,02 % / K |

| Connection | 12pin-connector |

Angle option (w)

| rev. max. | 3000 min⁻¹ |

| Output | open-collector |

| Internal pull up | 10 kΩ (5 V level) |

| External pull up | 24 V max. |

| I max: | 20 mA |

| Pulses/rev | 360 |

| Resolution | 1° |

| Detection of direction of rotation: |

| 2 pulses 90° phase shift Channel A leading for clockwise rotation of drive end |

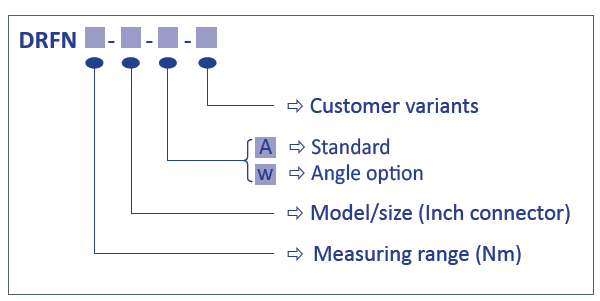

Ordering Code

Accessories

Analycer: ValueMasterbase GMV2

Cables

Static holders (SH)

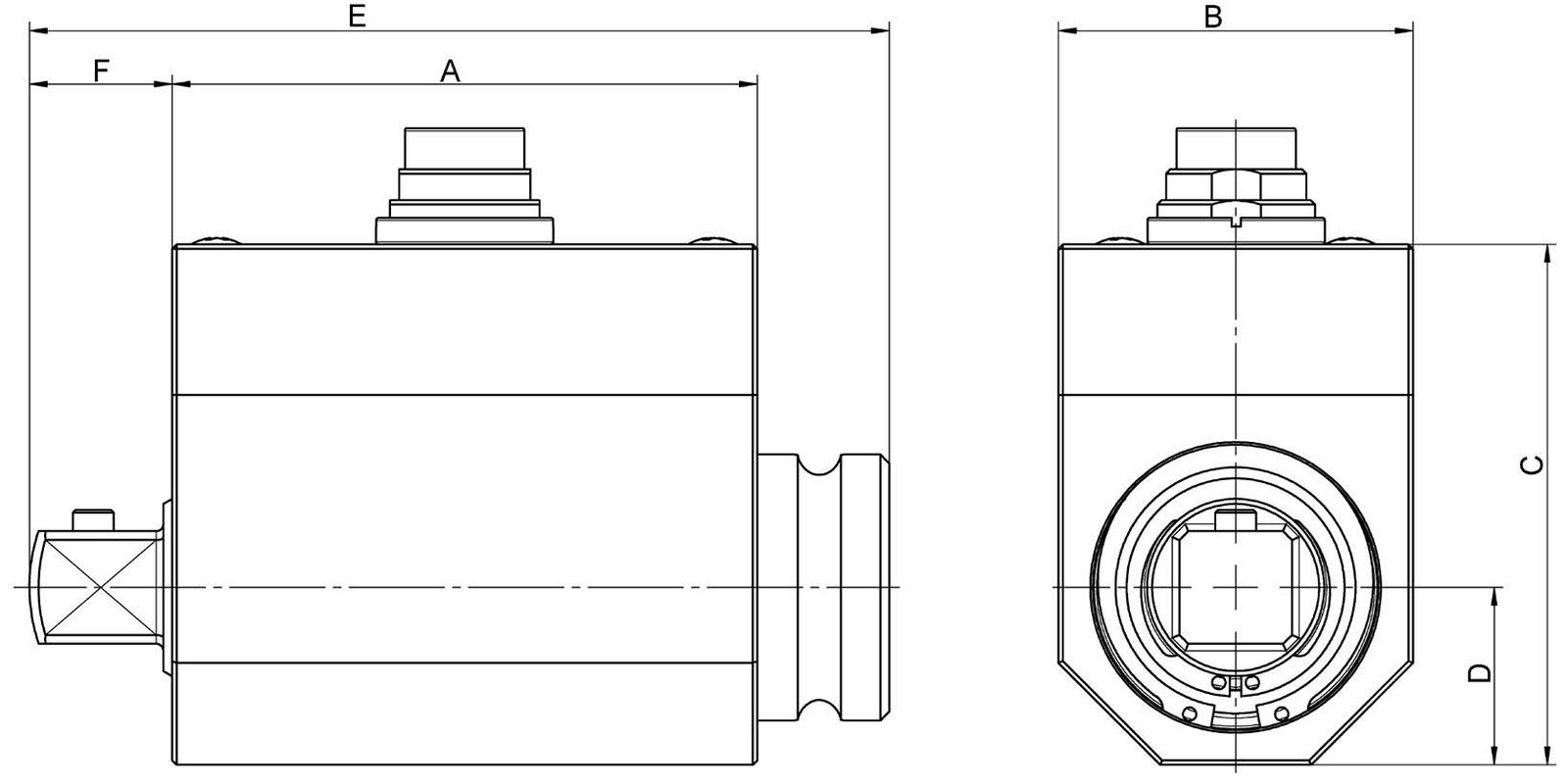

Mechanical Dimensions DRFN

Internal and external square DIN 3121 (ISO standard 1174: 1975)

Internal and external square DIN 3121 (ISO standard 1174: 1975)

Mechanical values and load limits DRFN

| Size (inch) |

nmax (l/min) | Torque range (± 0 – … Nm) |

Overload (%) |

A (mm) |

B (mm) |

C (mm) |

D (mm) |

E (mm) |

F (mm) |

Weight approx (g) |

|

| ¼“ | 12.000 | | 1 | 2 | 5 | 10 | 12 | 15 20 |

100 70 30 |

62 |

32 |

56 |

16 |

77 |

8 |

300 |

|

| ⅜“ | 12.000 | | 20 | 30 | 50 | 63 |

100 80 |

62 | 34 | 52 | 16,5 | 82 | 12 | 350 | |

| ½“ | 12.000 | 100 160 200 |

100 60 30 |

66 |

40 |

57 |

20 |

95 |

16 |

480 |

|

| ¾“ | 12.000 | | 200 | 300 | 500 |

100 50 |

66 | 46 | 65 | 23 | 110 | 24 | 800 | |

| 1“ | 12.000 | 1000 2000 |

50 30 |

66 | 52 | 71 | 25,5 | 127 | 31 | 1250 | |

| 1½“ | 7000 | | 2000 | 3000 | | 4000 | 5000 | | 6500 | 10.000 | |

100 50 |

86 |

92 |

108 |

46 |

178 |

44 |

4800 |

|

| t | ¼“- w | 12.000 | | 1 | 2 | 5 | 10 12 | 15 | 20 | |

100 80 50 30 |

66 |

32 |

51 |

16 |

82 |

9 |

250 |

| with rotation angle measuremen | ⅜“- w | 12.000 | | 20 |30 | 50 | 63 |

100 80 |

66 | 40 | 59 | 20 | 90 | 12 | 400 |

| ½“- w | 12.000 | 100 160 200 |

100 60 30 |

66 |

40 |

59 |

20 |

97 |

16 |

480 |

|

| ¾“- w | 11.500 | | 200 | 300 | 500 |

100 50 |

71 | 55 | 74 | 27,5 | 117 | 24 | 1050 | |

| 1“- w | 11.500 | | 1000 | | 50 | 72 | 56 | 73 | 28 | 132 | 30,5 | 1250 | |

| 1½“-w | 7.000 | | 2000 | 3000 | | 4000 | 5000 | | 6500 | 10.000 | |

100 50 |

86 |

92 |

108 |

46 |

178 |

44 |

4800 |

|

General tolerances DIN 2768-m

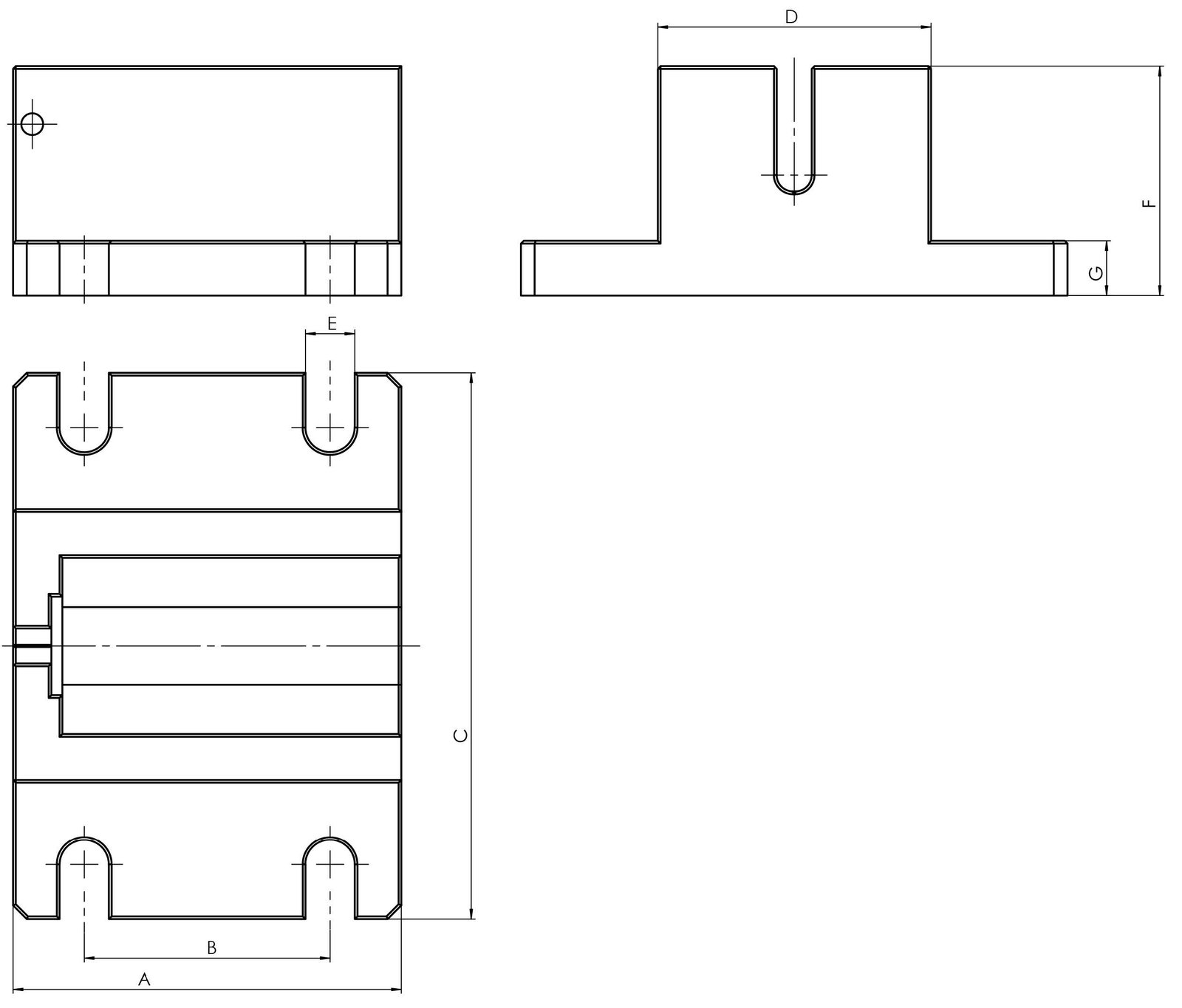

Mechanical Dimensions DRFN Static Holder (SH)

| Model | A | B | C | D | E | F | G |

| SH-DRFN ¼“ | 71 | 45 | 100 | 50 | 9 | 42 | 10 |

| SH-DRFN ⅜“ | 74 | 45 | 100 | 50 | 9 | 45 | 10 |

| SH-DRFN ½“ | 82 | 45 | 100 | 50 | 9 | 50 | 10 |

| SH-DRFN ¼“- w | 76 | 45 | 100 | 50 | 9 | 43 | 10 |

| SH-DRFN ⅜“- w | 78 | 45 | 100 | 50 | 9 | 45 | 10 |

| SH-DRFN ½“- w | 82 | 45 | 100 | 50 | 9 | 50 | 10 |

The static retainer (SH) is available on customer request for models DRFN ¾“, 1“, ½“ and DRFN ¾“-w, 1“-w, ½“-w.

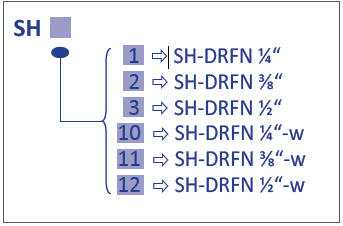

Ordering Code Static Holder

Reviews

There are no reviews yet.