Description

DIFFERENTIAL pressure transmitter

Nominal pressures from 0,5 bar to 2000 bar

AMPLIFIED outputs: 4-20mA, 10V or 5Volt

Linearity and hysteresis 0,20%

DIFFERENTIAL pressure transmitters of these series distinguish themselves for high reliability and long-term stability of mechanical and electrical features.

The sensitive part, in contact with pressure, is entirely made of 17-4 PH corrosion-proof stainless steel.

High vacuum thermal treatments which stainless steel is subjected to, ensure the correct functioning even when highly dynamic stresses are involved. Monolithic execution of measuring element, without any assembling via tight rings or gaskets, guarantees a high long-term stability, with negligible hysteresis and zero drift. Pressure is internally detected by two strain gauge full bridges, that guarantee the maintenance of performances even when dynamic stresses are involved.

Electronic section, realised via SMD technology, consists of a high precision instrumental amplifier and a stable supplier, protected against short circuits and polarity inversion.

Every pressure transmitter is entirely LASER welded and completely resin-encapsulated, to ensure insensitivity and a high degree of hermetic tight.

During production cycle, pressure transmitters are thermally compensated, tested and individually calibrated with the use of completely automated stations that analyse and record data.

These features make their use ideal in several industrial fields, as: pneumatic, hydraulic, food process control and, generally, whenever checking the difference between two exerted pressures is necessary.

They are installed on test benches, material testing machines, and used in research and development laboratories.

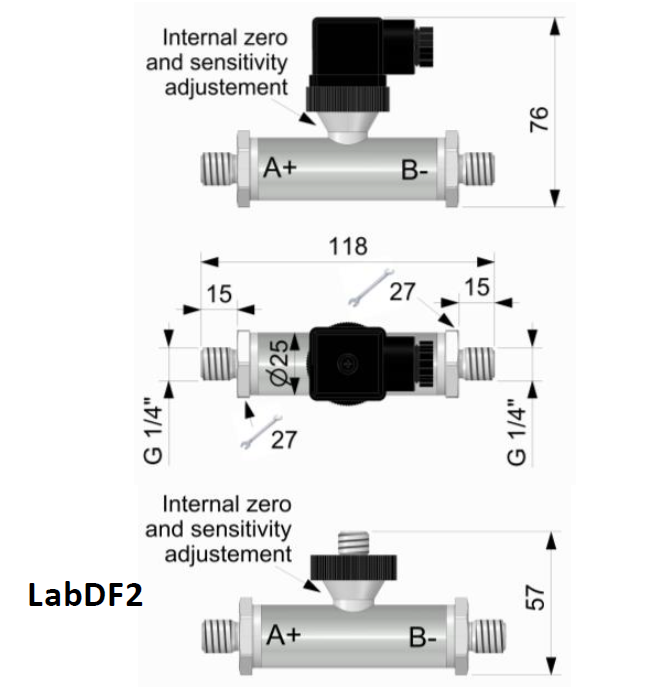

Dimensions

Technical Data

| TYPE | DF2 | LabDF2 |

|---|---|---|

| RELATIVE PRESSURE (R) Zero at atmospheric pressure |

0.5 – 1 – 2.5 bar 5 – 10 – 20 bar |

10 – 20 bar |

| ABSOLUTE PRESSURE (A) Zero at absolute vacuum |

50 – 100 – 250 – 350 – 500 – 700 bar *1000 – *1500 – *2000 bar |

|

| LINEARITY and HYSTERESIS | ± 0.20 % | ± 0.05 % |

| TEMPERATURE EFFECT (1°C) a) on zero b) on sensitivity |

± 0.015% ± 0.015% |

|

| NOMINAL SENSITIVITY | 4–20mA (3 wires) ±5 V, ±10 V |

|

| CALIBRATION TOLERANCE | ± 0.1% | |

| NOMINAL POWER SUPPLY | 4–20mA & ±5V → 12–24Vdc ±10V → 15–24Vdc |

|

| MAX. POWER SUPPLY MAX. ABSORPTION a) 3 wires LOADING RESISTANCE a) tension b) current INSULATION RESISTANCE ZERO BALANCE DIFF. VAR. SENSITIVITY RESPONSE FREQUENCY |

28Vdc

30mA min. 3 kΩ |

|

| LIMIT MECHANICAL VALUES a) service pressure b) max permissible pressure c) breaking pressure d) highly dynamic pressure |

100% 150% >300% 75% |

|

| REFERENCE WORKING STORAGE TEMPERATURE |

+23°C -10/+70°C -20/+80°C |

|

| PROCESS COUPLING WRENCH TIGHTENING TORQUE |

1/4″Gas (*1/2″Gas) BSP Male 27 mm 28 Nm |

|

| PROTECTION CLASS (EN 60529) SENSOR EXECUTION MATERIAL ELECTRICAL CONNECTION |

IP65 INOX 17-4 PH DF2: Connector DIN 43650 A/ISO 4400 LabDF2: M12×1 + 4 poles 3m shielded cable |

|

OPTION

MOCA certification for food applications (pressure ≥ 20bar)

Functioning example

| SIGNAL OUTPUT | ||||

| Port | Pressure | 4-20mA* | ±5V | ± 10 V |

| A + | 0 | 4 mA | 0 | 0 |

| B – | 0 | |||

| A + | FS | 20 mA | + 5V | + 10V |

| B – | 0 | |||

| A + | 0 | max 0.8 mA | – 5V | – 10V |

| B – | FS | |||

| A + | FS | 4 mA | 0 | 0 |

| B – | FS | |||

*In the version with mA output, when pressure increases in the port B-, the signal decreases down to 0.8mA then stops even if pressure continues to increase.

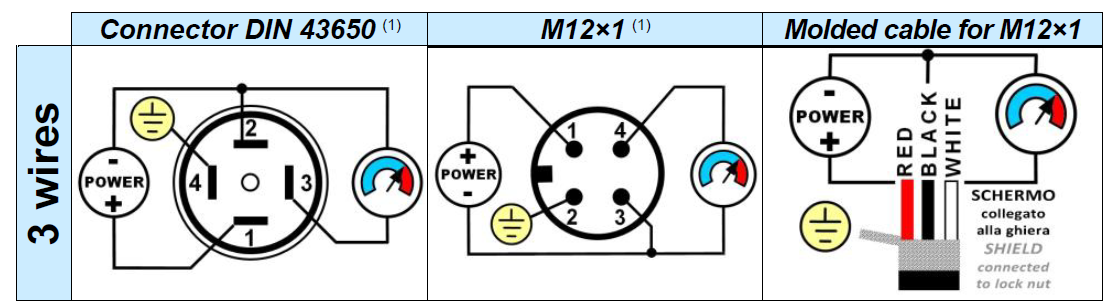

Electrical connections

![]() Connected to body of the pressure transmitter.

Connected to body of the pressure transmitter.

(1) ZERO and SENS. adjustment is accessible by unscrewing the connector.

Reviews

There are no reviews yet.