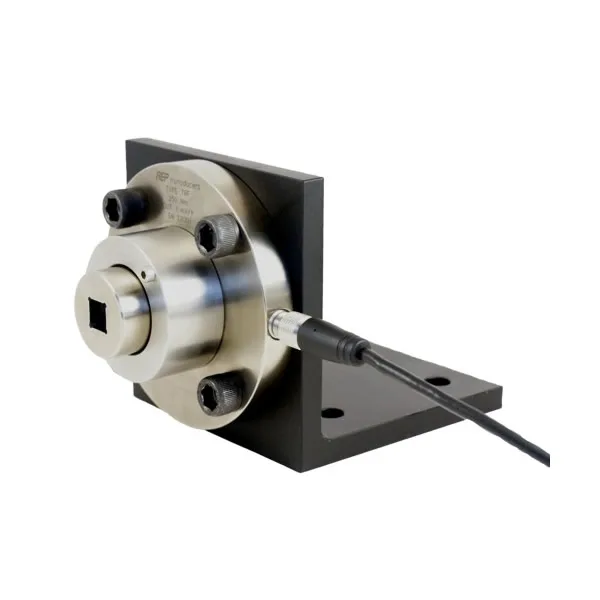

Description

TRF STATIC torque transducers

STATIC torque transducer for clockwise and anticlockwise measurements Attack female FRAMEWORK Nominal loads from 100 Nm to 1000 Nm Linearity and Hysteresis 0.20% and 0.10% Standard output ± 1mV / V

CHEAP

Dimensions[mm]

| CODE | LOAD | A | B | C |

| MTRF100NM | 100 N·m | 16 | 1/2” | 60 |

| MTRF250NM | 250 N·m | 16 | 1/2” | 60 |

| MTRF500NM | 500 N·m | 24 | 3/4” | 70 |

| MTRF1KNM | 1000 N·m | 24 | 3/4” | 70 |

Technical Data

| STATIC NOMINAL TORQUE | 100 – 250 – 500 – 1000 N·m |

| LINEARITY and HYSTERESIS | ≤ ± 0.20 % |

| TEMPERATURE EFFECT (1°C): a) on zero b) on sensitivity |

≤ ± 0.02% ≤ ± 0.02% |

| NOMINAL SENSITIVITY SENSIVITY TOLERANCE |

1 mV/V ≤ ± 0.5% |

| Input resistance Output resistance | 825 ± 50 W 700 ± 2 W |

| NOMINAL POWER SUPPLY MAX. POWER SUPPLY INSULATION RESISTANCE ZERO BALANCE |

1-15 V 18 V >2 GW ≤ ± 1% |

| LIMIT MECHANICAL VALUES REFERRED TO NOMINAL TORQUE: a) service torque b) max. permissible torque c) breaking torque d) highly dynamic torque |

100% 150% >300% 70% |

| REFERENCE TEMPERATURE WORKING TEMPERATURE RANGE STORAGE TEMPERATURE RANGE |

+23°C -10/+70°C -20/+80°C |

| PROTECTION CLASS (EN 60529) SENSOR EXECUTION MATERIAL ELECTRICAL CONNECTION |

IP40 INOX M12 5 Poli Maschio |

| PROCESS COUPLING (UNI ISO 1174-1): 100 – 250 N·m 500 – 1000 N·m |

o 1/2” o 3/4” |

Accessories (purchased separately)

Bracket for vertical mounting

Code: ST

Joint simulator

Code: GN100

Code: GN250

Code: GN500

Code: GN1000

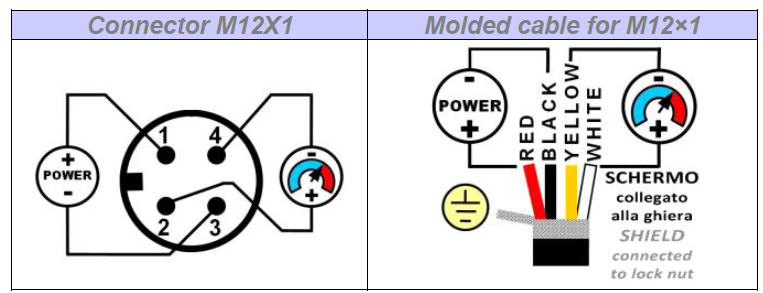

Electrical Connections

PVC 105°C shielded cable, Ø 5.2mm with 4 tinned Ø 0.35mm2 conductors. Shield connected to the body of the torque meter.

Reviews

There are no reviews yet.