Description

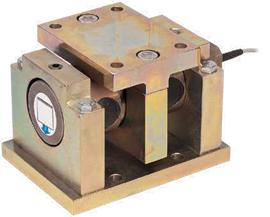

KDH-3 Weigh Module

Features

All Stainless Steel

22.5, 45, and 112.5 klb capacities

Seismic and wind resistant self-checking design

Resistant to sideloads

Accommodates process dynamics and thermal expansion

Fault protected transducer excitation

Application: Process Weighing & Batching,Hazardous Areas

Certificates: cFMus

Combined Error: 0.11-2 %

Environment Protection Class: NEMA 4x,NEMA 6,IP67,IP66,IP65,IP54,IP20

Industry: Metal,Mining,Chemical,Pharmaceutical,Food & Beverage

Material: Stainless Steel

Max Capacity: k lb: 25-115

Max Capacity: kN: 100-500

Max Capacity: ton: 10-50

Product Type: Weigh Modules & Load Cells

CONFIGURATION

High Capacity Weigh Modules

DESIGN FEATURES

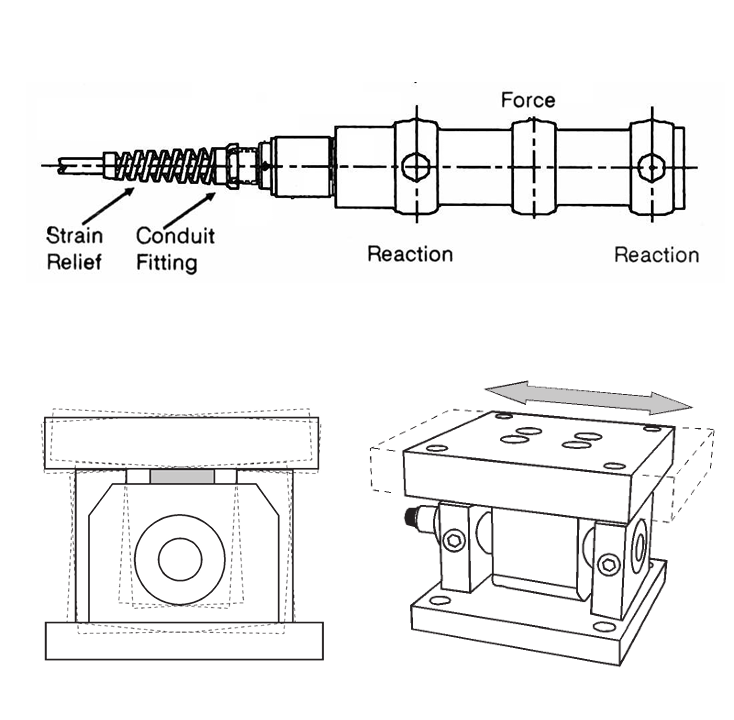

The cylindrical double ended shear beam module is designed to measure shear stresses induced by an applied load without errors caused by thermal expansion. The combination beam and mounting hardware is ideally suited for use on large dynamic process vessels where temperature changes, vibration, and possibly seismic forces are encountered. The cylindrical tube type transducer offers several advantages over rectangular shear beam designs. Superior resistance to moisture contam ination is accomplished by eliminating gaged pockets on the outside of the beam. Instead, the KDH uses strain gages applied to the inside wall of the tube. In addition, the cable entry is equipped with a conduit itting for cable protection and is internally potted. Structurally, the cylindrical tube is equally strong in both the vertical and horizontal planes. Unlike rectangular shear beams that are typically weaker in the horizontal plane, KDH modules are less affected by sideloads induced by vibration, temperature, or process dynamics. The design of the mounting hardware eliminates the need for highly stressed pins and/or bolts to attach the beam. This reduces the adverse effects of varying edge and point stresses and makes the overall module less susceptible to calibration changes. Low proile design and symmetrical mounting bolt patterns make KDH modules easy to install on new or existing structures and vessels.

ination is accomplished by eliminating gaged pockets on the outside of the beam. Instead, the KDH uses strain gages applied to the inside wall of the tube. In addition, the cable entry is equipped with a conduit itting for cable protection and is internally potted. Structurally, the cylindrical tube is equally strong in both the vertical and horizontal planes. Unlike rectangular shear beams that are typically weaker in the horizontal plane, KDH modules are less affected by sideloads induced by vibration, temperature, or process dynamics. The design of the mounting hardware eliminates the need for highly stressed pins and/or bolts to attach the beam. This reduces the adverse effects of varying edge and point stresses and makes the overall module less susceptible to calibration changes. Low proile design and symmetrical mounting bolt patterns make KDH modules easy to install on new or existing structures and vessels.

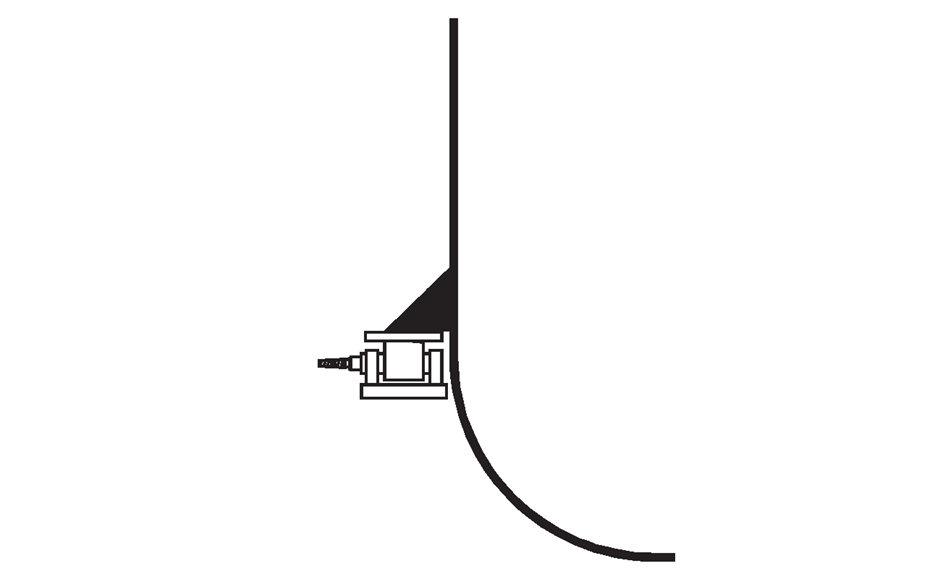

TYPICAL KDH WEIGH MODULE MOUNTING ARRANGEMENTS

High Capacity Weigh Modules

DIMENSIONS

High Capacity Weigh Modules

SPECIFICATIONS

| Parameter | Value |

|---|---|

| LOADING SPECIFICATIONS — % RATED CAPACITY | |

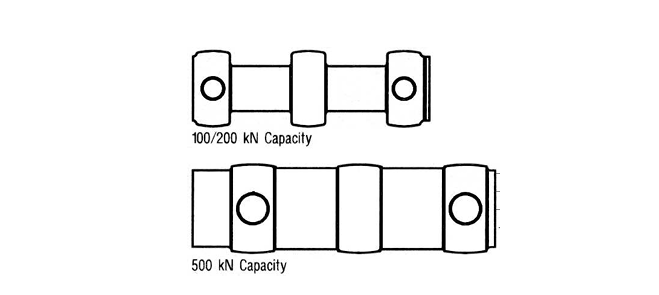

| Capacities | 100 kN / 200 kN / 500 kN |

| Load, safe | 150% / 150% / 150% |

| Load, ultimate | 300% / 300% / 300% |

| Uplift, safe | 150% / 75% / 75% |

| Uplift, ultimate | 300% / 150% / 150% |

| Sideload (Axial), safe | 100% / 50% / 50% |

| Sideload (Axial), ultimate | 200% / 100% / 100% |

| Sideload (Transverse), safe | 100% / 50% / 50% |

| Sideload (Transverse), ultimate | 200% / 100% / 100% |

| PERFORMANCE / ELECTRICAL | |

| Input resistance | 700 Ω ±7 Ω |

| Output resistance | 700 Ω ±7 Ω |

| Rated output (RO) | 2.0 mV/V ±0.1% |

| Zero balance | 1% RO |

| Combined error (best fit) | 0.12% RO |

| Creep (20 minutes) | 0.05% RO |

| Repeatability | 0.02% RO |

| Recommended excitation | 10 VAC or VDC (20 V max.) |

| TEMPERATURE | |

| Temperature range, safe | –34.4 to 104.4 °C (–30 to 220 °F) |

| Temperature range, compensated | –1 to 54 °C (30 to 130 °F) |

| TEMPERATURE EFFECTS (30 to 130 °F) | |

| Zero balance | 0.0025% RO per °F |

| Span | 0.0015% Reading per °F |

| MATERIAL / PROTECTION | |

| Beams and brackets | 15-5 PH or 17-4 PH stainless steel |

| Environmental class | NEMA 4X, IEC IP67 |

| Moisture / vibration protection | IEC 68-2-4 Test D, 200 cycles (min.) |

| Corrosion protection | All units electropolished stainless steel (mounting hardware) |

| DEFLECTION UNDER LOAD & WEIGHT | |

| Deflection (100 kN) | 0.51 mm (0.020 in) |

| Deflection (200 kN) | 0.33 mm (0.013 in) |

| Deflection (500 kN) | 0.31 mm (0.012 in) |

| Weight (100 kN) | 45 lb |

| Weight (200 kN) | 46 lb |

| Weight (500 kN) | 75 lb |

| TERMINATION | |

| Electrical connection | 10 m (32 ft 10 in) cable with conduit fitting (100 / 200 / 500 kN) |

| DOCUMENTATION | |

| Outline drawing | #468140-3 |

BLH Nobel is continually seeking to improve product quality and performance. Speciications may change accordingly. Many performance speciications are proven on a statistical sample basis.

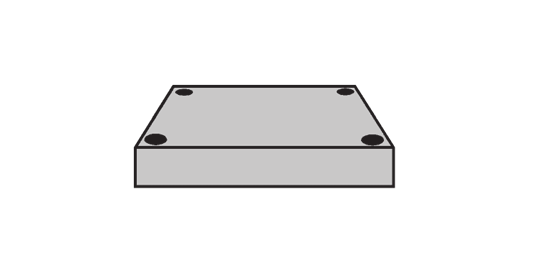

THERMAL INSULATION PADS

Thermal insulation pads reduce heat conducted from a heated vessel. The pads are made of rigid laminate with extremely low thermal conductivity, BLH Nobel recommends using insulation pads if the vessel mounting surface temperature exceeds 52°C (130°F). Pads are 1 in thick with bolt spacing identical to module top plates.

SIMULATED WEIGH BEAMS

Optional simulated (dummy) beams are used in place of actual KDH transducers during the installation process. Using simulated beams eliminates the risk of damaging the KDH transducer while welding or positioning the weigh vessel. All critical simulated beam dimensions are identical to actual KDH outline speciications.

Reviews

There are no reviews yet.