What is a Shaking Incubator?

A shaking incubator is one of the most commonly used basic pieces of equipment in life sciences, microbiology, cell culture, and fermentation experiments. It supplies CO₂ to maintain the pH of the culture medium, while simultaneously providing temperature control and shaking, allowing microorganisms or cells to grow uniformly and rapidly.

Qualification Evaluation Items

Verification of Supporting Equipment

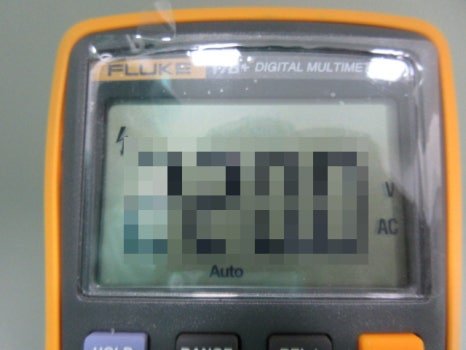

This item involves verifying whether the supporting facilities on-site meet the required standards.

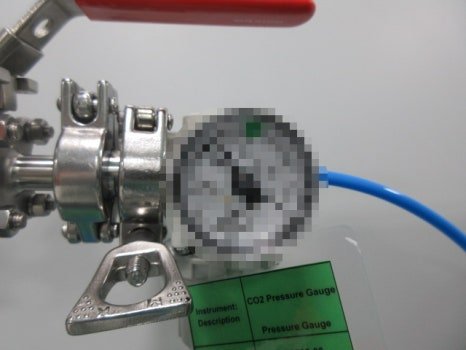

In shaking incubators, it is mainly used to check CO₂ supply pressure and electrical supply voltage.

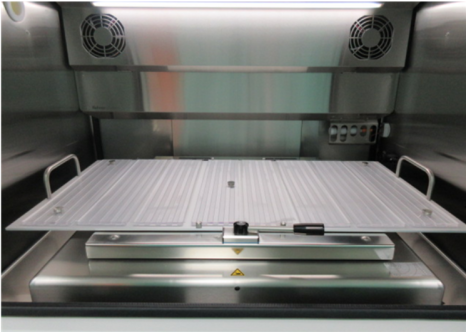

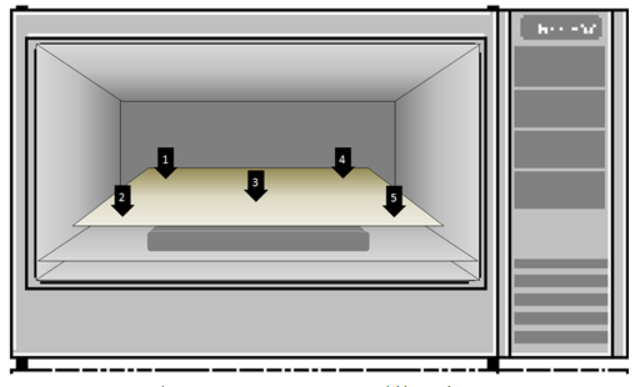

Verification of Temperature Distribution

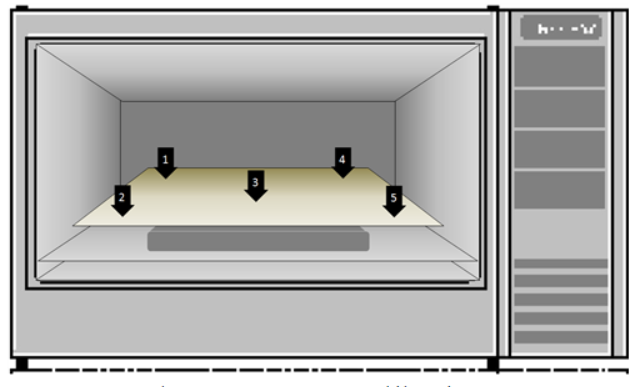

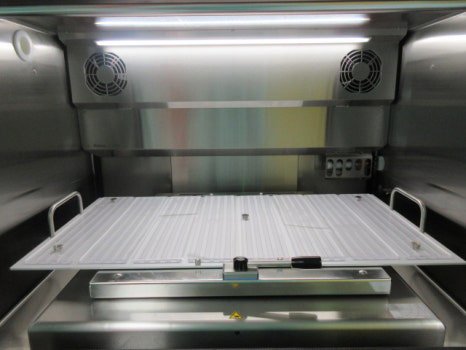

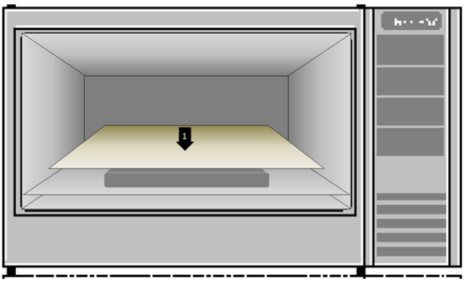

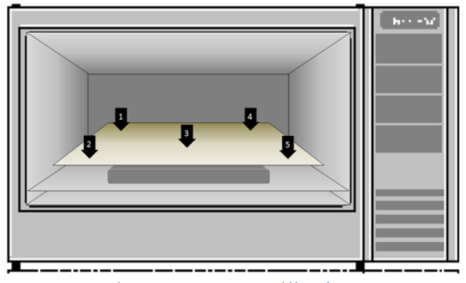

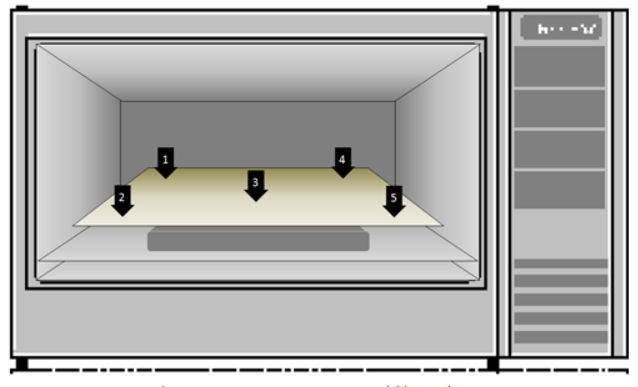

This evaluation item involves placing temperature data loggers evenly inside the shaking incubator to verify that the temperature is uniformly distributed throughout the chamber.

Verification of Humidity

A hygrometer is placed inside the incubator, and the device is operated under the user-specified process conditions.

The internal humidity is measured over a minimum of 24 hours to verify that it remains stable.

This test is sometimes conducted together with temperature distribution verification to evaluate both temperature and humidity simultaneously.

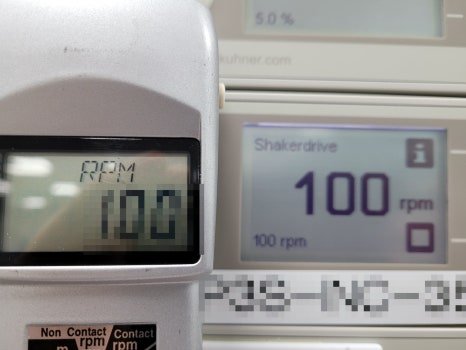

Verification of Shaking/Rotation Speed

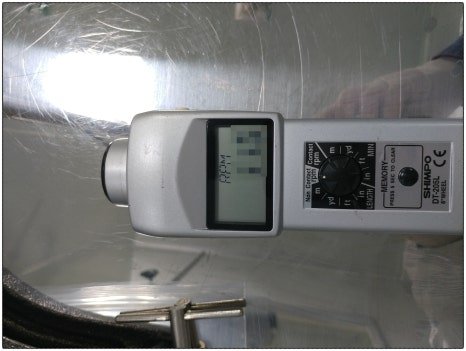

Among shaking incubators, this evaluation item checks whether the device that performs shaking through rotational motion operates at a consistent speed according to the set rotation speed.

Verification of Shaking Speed

This evaluation item checks whether the shaking speed of non-rotational shaking methods in a shaking incubator is consistently maintained according to the set speed.

Verification of CO₂ Concentration

This evaluation item verifies whether the CO₂ concentration set in the shaking incubator matches the actual measured concentration.

Qualification Evaluation Case Collection

This is a collection of cases in which shaking incubator qualification evaluations were conducted.

- Yongin Research Center

This case involves a request from the research center and includes both the Installation Qualification (IQ) and Operational Qualification (OQ) of a shaking incubator.

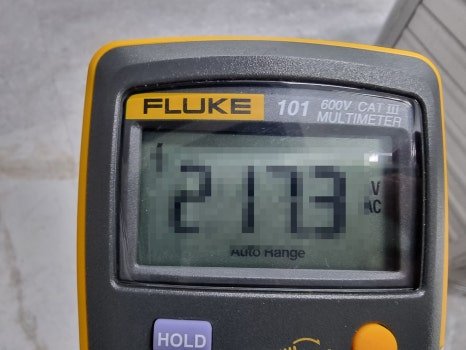

First, a supporting equipment verification was conducted, checking the CO₂ supply pressure and electrical supply voltage as part of the evaluation.

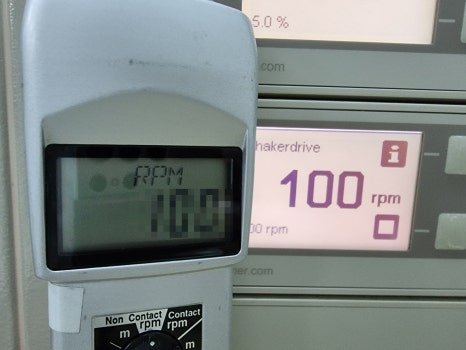

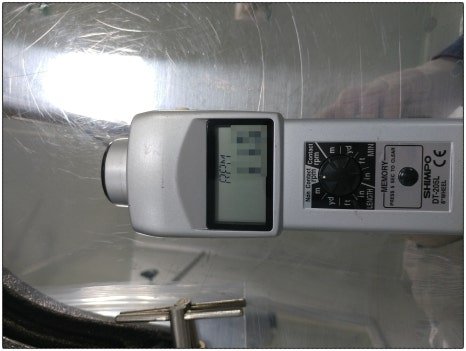

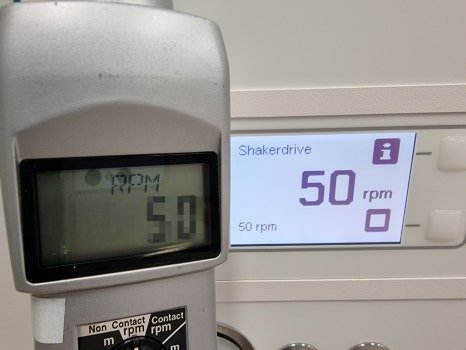

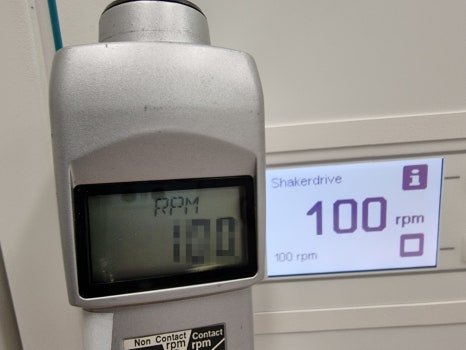

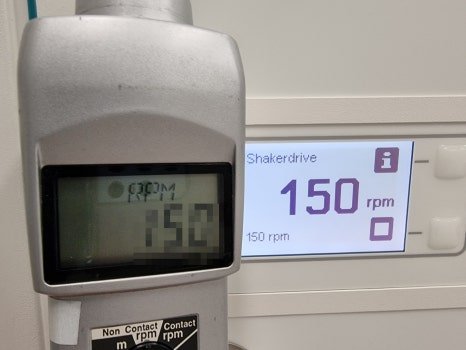

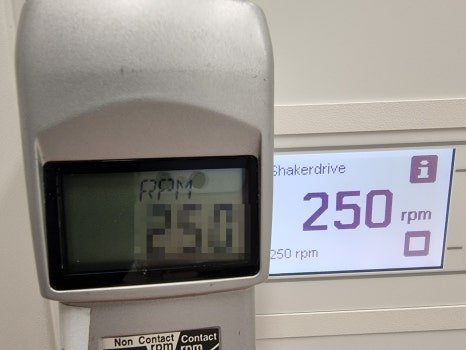

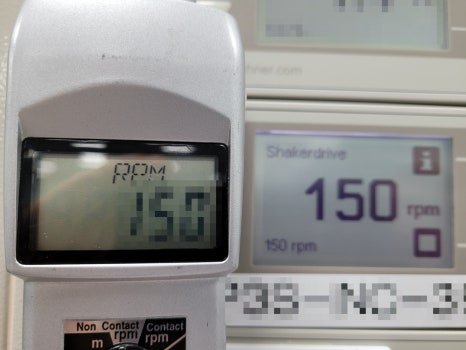

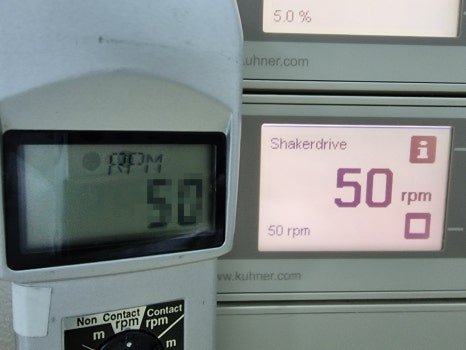

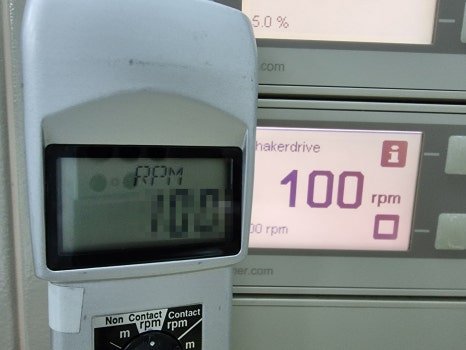

Next, shaking (rotation) speed verification was conducted.

The speed was divided into five intervals, and measurements were repeated three times for each interval during the evaluation.

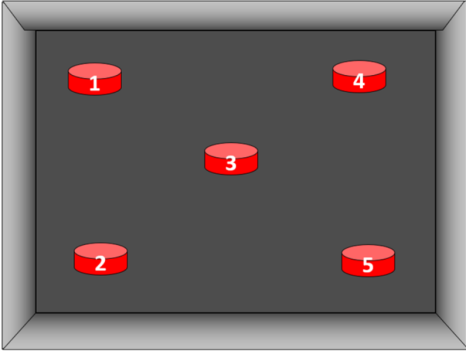

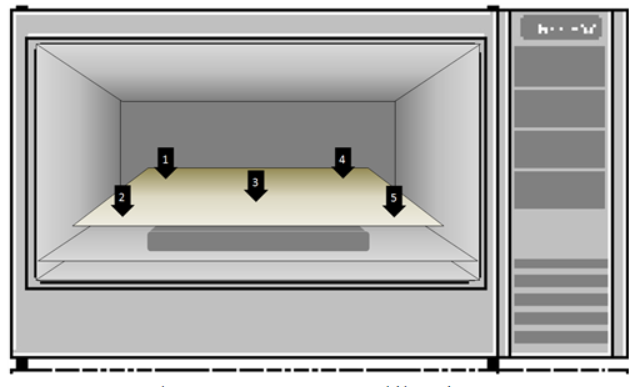

With the shaking incubator empty, temperature data loggers were placed at the four corners and the center of the incubator platform, and a humidity data logger was installed at the center.

The incubator was operated under user-specified process conditions for 24 hours to verify the internal temperature and humidity.

Finally, to verify CO₂ concentration, the incubator was set to the user-specified CO₂ level.

After allowing sufficient stabilization, a CO₂ analyzer was placed next to the device to measure the CO₂ concentration.

2. Anyang Company

This case involves both the Installation Qualification (IQ) and Operational Qualification (OQ) of a shaking incubator.

First, a supporting equipment verification was conducted, checking the CO₂ supply pressure and electrical supply voltage.

Next, the rotation speed of the shaking incubator was verified.

Afterward, CO₂ concentration verification and internal temperature distribution assessment were conducted.

The measurement data were recorded and documented to complete the process.

3. Gyeonggi Hwaseong Research Center

This case involves only the Operational Qualification (OQ) of a shaking incubator.

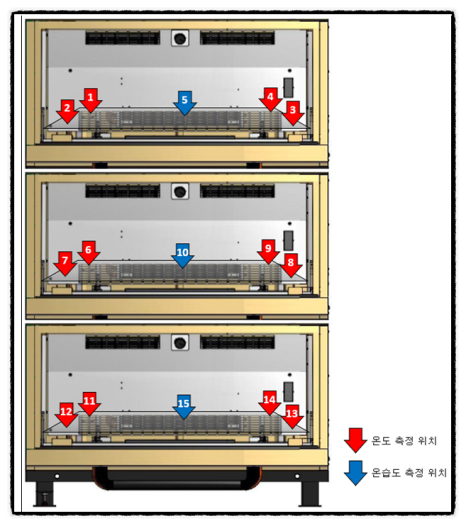

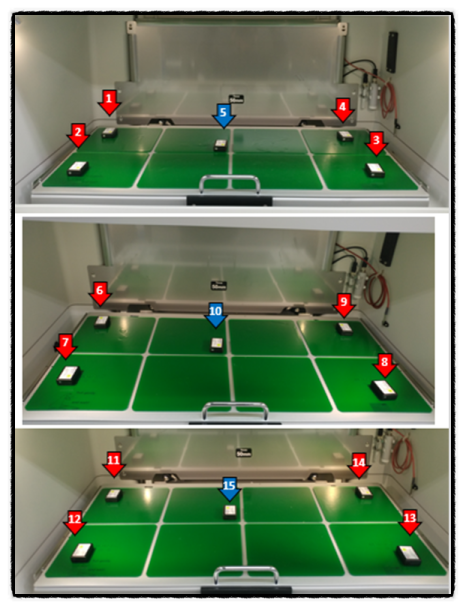

Temperature and humidity data loggers were placed at the corners and center of each of the three layers of the incubator.

This setup was used to verify whether the internal temperature and humidity were maintained according to the set values.

Next, measurement devices were placed on each layer inside the incubator, and measurements were repeated three times on each layer.

Finally, CO₂ analyzers were installed on each layer of the incubator, and measurements were repeated three times per layer to complete the qualification evaluation.

4. Gyeonggi Hwaseong Dongtan Company

This case involves a performance qualification (PQ) conducted on a shaking incubator.

Temperature distribution and shaking (rotation) speed verifications were conducted.

5. Incheon Company

This case involves both the Installation Qualification (IQ) and Operational Qualification (OQ) of a shaking incubator.

First, a supporting equipment verification was conducted, checking the CO₂ supply pressure and electrical supply voltage.

Next, rotation speed measurements were conducted by performing three consecutive measurements for each speed interval, repeated twice.

The CO₂ concentration was set according to the user-specified conditions, and after all parameters stabilized, a CO₂ analyzer was used to measure the concentration inside the incubator three consecutive times for each condition.

Temperature data loggers were installed at the corners and center of the incubator platform.

The device was then operated under user-specified process conditions to measure the internal temperature distribution for a minimum of 24 hours.

6. Incheon Company

This case involves the Operational Qualification (OQ) of a shaking incubator.

The speed range was divided into five intervals, and measurements were conducted three consecutive times for each interval.

The user-specified CO₂ concentration was set, and after all parameters stabilized, a CO₂ analyzer was placed in the incubator to measure the CO₂ concentration three consecutive times.

Temperature data loggers were installed at the four corners and center of the incubator.

The device was then operated under user-specified process conditions to measure the internal temperature distribution for a minimum of 24 hours.

7. Incheon Company

This case involves a company that newly installed a shaking incubator and conducted both Installation Qualification (IQ) and Operational Qualification (OQ).

We began by verifying the utility systems, confirming the CO₂ supply pressure and the power supply voltage.

With the instrument empty, we configured it according to the user-specified measurement conditions and, once all parameters—including rotational speed—had stabilized, measured the incubator’s internal rotational speed.

As with the rotational speed, we set the CO₂ concentration according to the user-specified settings. After waiting for all parameters to stabilize, we measured the CO₂ concentration using a CO₂ analyzer.

Finally, temperature data loggers were placed at each corner and the center inside the incubator. The device was then operated according to the user-specified process conditions, and the internal temperature distribution was measured over a 24-hour period.

8. A company located in Geumcheon-gu, Seoul

This case involved conducting both the Installation Qualification (IQ) and Operational Qualification (OQ) for a shaking incubator.

As part of the utility verification, we checked the CO₂ supply pressure and the electrical supply voltage.

After emptying the incubator, we set the rotational speed according to the user-specified conditions. Once all parameters had stabilized, we performed three consecutive measurements for each section.

As with the rotational speed, we set the conditions according to user specifications. Once the parameters had stabilized, we measured the CO₂ concentration using a CO₂ analyzer.

Temperature data loggers were installed at the four corners and the center inside the incubator. The device was then operated according to user-specified conditions, and measurements were taken over a 24-hour period.

A humidity data logger was installed at the center of the incubator. The device was then operated according to the specified conditions, and the internal humidity was measured over a 24-hour period.

If you have any questions or need a solution, please let us know your required specifications and intended use. You can leave your inquiry in the quotation request section at the bottom of this page, and we will be happy to assist you.

CASScale Korea is always committed to providing you with useful information.

No Comments