Description

Overview

In modern society, strain gauges are essential measurement tools used to verify the functionality and safety of machines and structures. Adhesive-type strain gauges were first developed in the United States in 1938, and in Japan, foil-type strain gauges have been manufactured since 1962. They are important instruments for measuring the strength and properties of various materials, including metals, rubber, plastics, and ceramics.

A strain gauge consists of a thin metal foil, just a few microns thick, bonded onto an electrically insulating base (such as polyimide or polyester). The gauge pattern is formed using a photo-etching process, and the grid resistance is adjusted to a standard value. The temperature coefficient of resistance of the metal foil is also controlled to match the coefficient of thermal expansion of the material being measured, resulting in a self-temperature-compensated structure. This allows for accurate stress and strain measurements with minimal temperature effects, even on materials such as steel, stainless steel, and aluminum alloys.

| Type | Uniaxial Gauge | Biaxial Gauge | Triaxial Gauge | Stress Concentration Gauge |

|---|---|---|---|---|

| Basic Model | N11… | N22… | N32… | R11,N51,R51… |

| With Lead Wires | N11…VS… | N22…VS… | N32…VS… | R11,N51,R51…VS… |

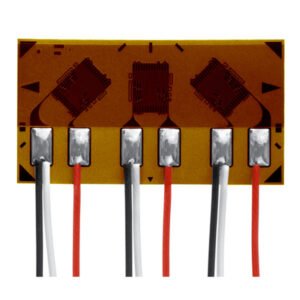

| Basic pattern |  |

|

|

|

| Type | Shear Gauge | Crack Gauge | Pipe Gauge |

|---|---|---|---|

| Application | Shear stress and torque measurement | Crack detection | Bolt axial force measurement, overview |

| Basic Model | Z11… | X11… | P11… |

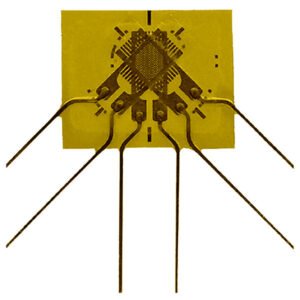

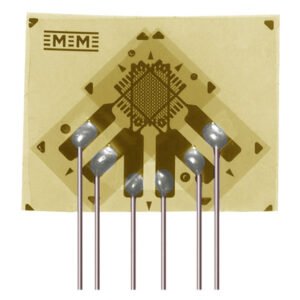

| Basic pattern |  |

|

|

Reviews

There are no reviews yet.