What is a CO₂ Incubator?

A CO₂ incubator is a device that accurately simulates the environment in which human cells live — including temperature, humidity, pH, and CO₂ concentration — to culture cells. It serves as an artificial biological environment system that maintains the physiological conditions necessary for cell survival and growth.

Checking CO₂ Concentration

According to the experimental conditions, the process is carried out under each loading state.

After setting the CO₂ concentration, measurements are taken immediately after stabilization and again 24 hours after stabilization to verify the CO₂ concentration.

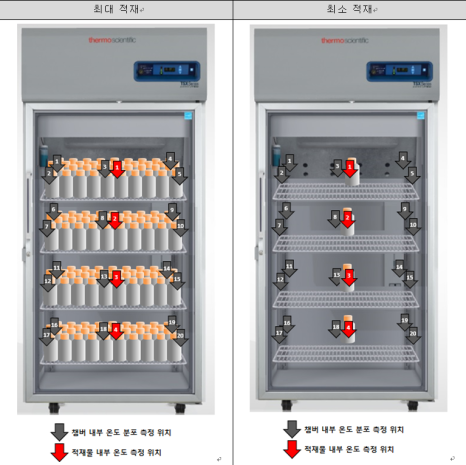

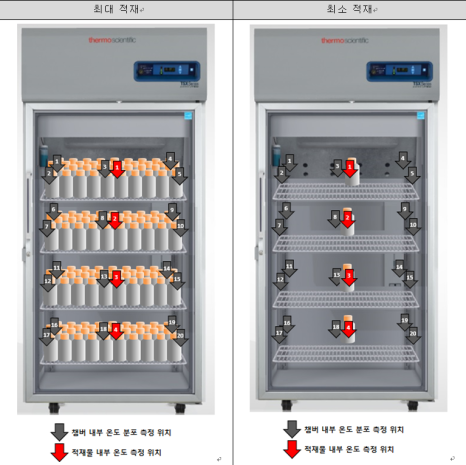

Checking Temperature Distribution Under Loading Conditions

Measurements are conducted under maximum loading conditions or by considering limit and normal conditions, including the worst-case scenario.

The chamber is arranged with actual loads in a specified loading pattern to simulate conditions similar to real culture environments, and measurements are performed under these conditions.

Verification of Control Capability Under Abnormal Conditions

To verify control capability under abnormal conditions:

Power-Outage Test: After the incubator has stabilized, the power is intentionally cut off. Using a temperature data logger, the time until temperature deviation occurs inside the chamber is recorded to evaluate temperature maintenance during a power outage.

Door-Opening Test: The incubator door is intentionally opened to induce a temperature deviation. After closing the door and resuming normal operation, temperature recovery is monitored using a temperature data logger.

Case Collection

- Cheonan Research Center

This case involves a performance qualification (PQ) conducted on a CO₂ incubator.

First, CO₂ concentration measurements were conducted.

The concentration was adjusted according to the user’s operating conditions, and measurements were taken three times immediately after stabilization.

Then, after 24 hours of stabilization, the CO₂ concentration was measured again to determine the duration of CO₂ maintenance.

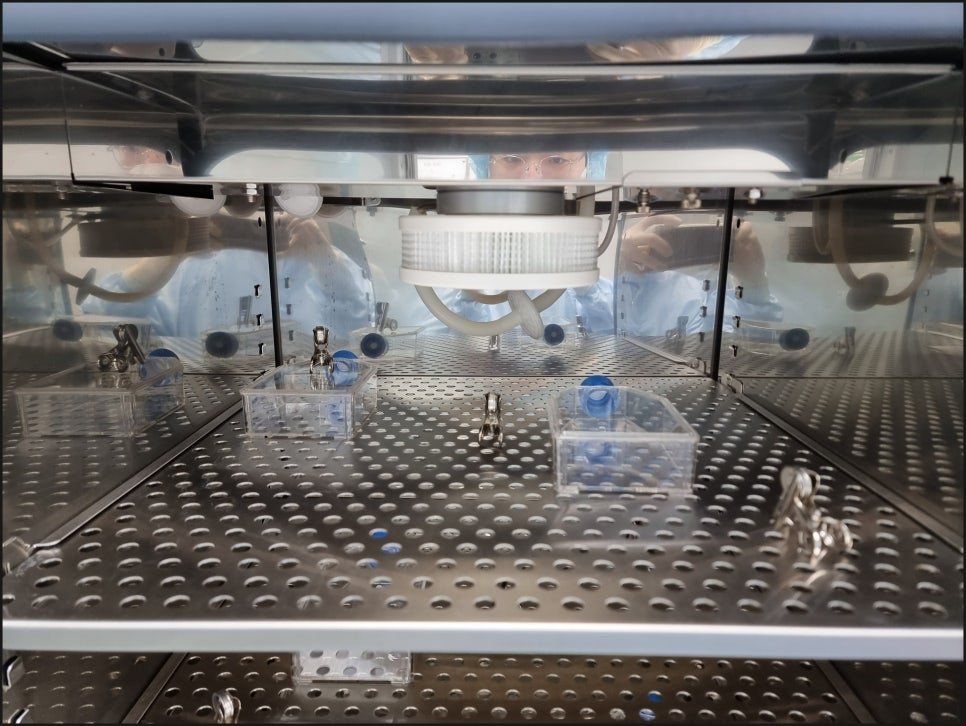

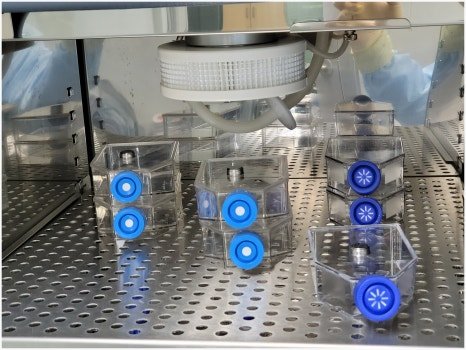

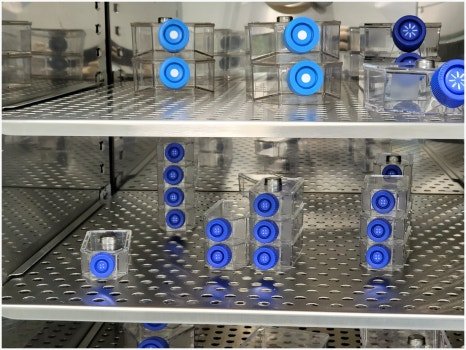

To verify the temperature distribution under loading conditions, materials used for cell culture were placed inside the incubator.

Temperature data loggers were positioned within the incubator, and the device was operated for 24 hours while measurements were recorded.

2. Cheonan Research Center

This case presents a performance qualification (PQ) conducted on a CO₂ incubator.

ChatGPT의 말:

The test was conducted by considering limit conditions, including worst-case scenarios, as well as normal conditions. Actual loads were arranged inside the chamber in a specified loading pattern to simulate conditions similar to real culture environments.

CO₂ concentration was first set, and measurements were taken immediately after stabilization.

The CO₂ concentration was measured again after 24 hours to assess maintenance over time.

The measurements were conducted by considering limit conditions, including worst-case scenarios, as well as normal conditions. Actual loads were arranged inside the chamber in a specified loading pattern to simulate conditions similar to real culture environments before starting the measurements.

3. Seongnam GMP Center

This case involves a re-performance of the CO₂ incubator’s performance qualification (PQ) due to process changes.

CO₂ concentration measurements were conducted under each loading condition according to the experimental setup. After operating the equipment under normal conditions and allowing the internal CO₂ to stabilize, measurements were taken three consecutive times using a gas analyzer.

Based on the conditions determined during the test setup, the procedure was conducted at the maximum load.

The equipment was operated in accordance with the manufacturer’s manual and standard operating procedures. A temperature data logger was installed, and the temperature distribution inside the incubator was measured over a period of 72 hours.

The test was conducted after loading materials similar to actual operating conditions.

Temperature recovery time and temperature maintenance during a power outage were then evaluated.

If you have any questions or require a solution, please provide the specifications you need and how you intend to use the equipment, then leave your inquiry in the “Request a Quote” section at the bottom of this page.

KAS Scale Korea will be happy to assist you and will continue to provide valuable information.

No Comments