설명

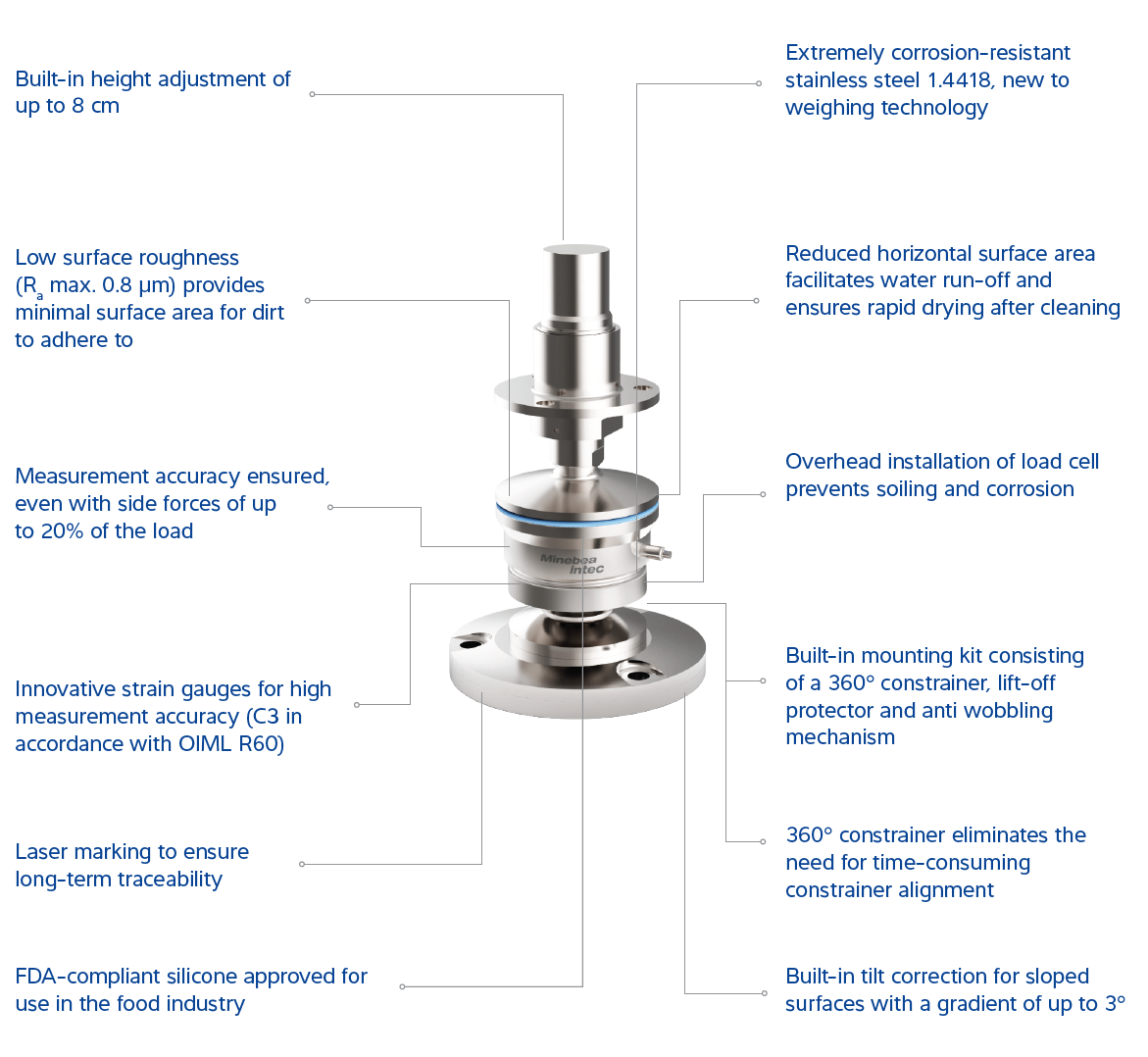

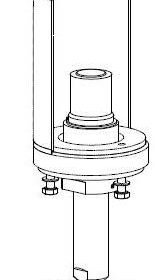

Weighing module Novego®

Hygienic all-in-one solution for reliable weighing of vessels

The weighing module Novego® was specifically developed to meet the increasingly stringent requirements of the food industry. This hygienic all-in-one solution boasts a range of innovative properties to ensure simple, error-free installation and maximum resistance to lateral forces.

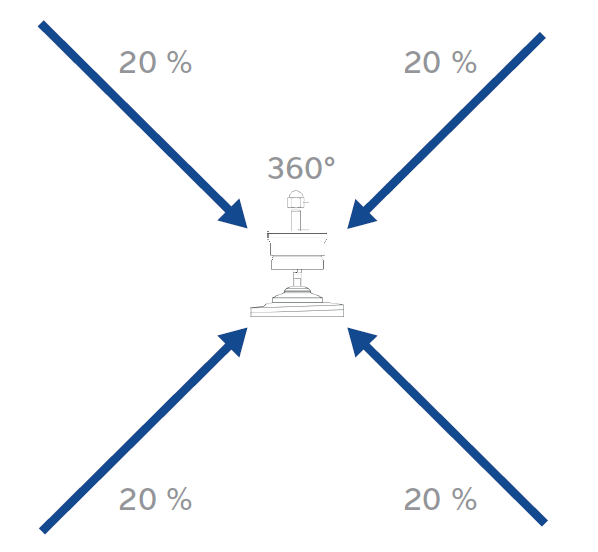

Unique on the market: reliable measurement accuracy – even with high side forces

- Minimum sensitivity to side forces: the weighing module Novego® reliably absorbs lateral forces. The six strain gauges ensure maximum measurement accuracy and prevent incorrect quantities, even when using mixers.

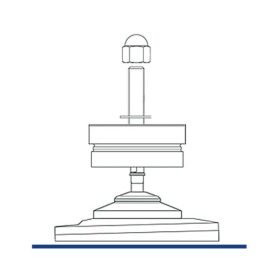

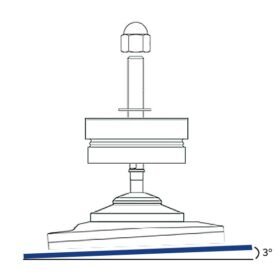

- The built-in height adjuster and innovative tilt correction for sloped surfaces ensure intuitive installation of the Novego®, meaning it is ready for operation immediately.

- The optimal accessibility of all components enables quick, easy and efficient cleaning, and prevents soiling.

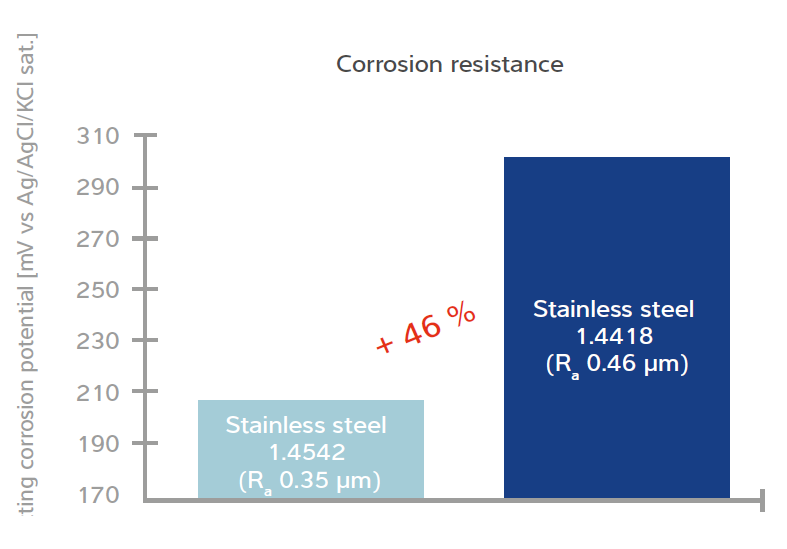

- The high product quality and corrosion resistance of the Novego® reduce set-up costs and machine downtime.

Novego®: one weighing module, a world of advantages

Novego® ensures process reliability, measurement accuracy and rapid cleaning. The exceptional corrosion resistance

of the stainless steel and the product design in accordance with EHEDG guidelines make the weighing

module resistant to dirt, water and even aggressive cleaning products.

The weighing module Novego® was developed in line with the stringent design

standards of the European Hygienic Engineering and Design Group (EHEDG).

Technological advancement is the sum of many small details

Technical Data

Weighing module Novego® / PR 6261 (125kg – 2t)

|

Parameter |

Description |

Abbr. |

D1 |

C3 |

Unit |

|

|

Accuracy class |

|

|

0.04 |

0.015 |

% Emax |

|

|

Minimum dead load |

Lowest limit of specified measuring range |

Emin |

0 |

|

% Emax |

|

|

|

|

|

|

125, 250, |

|

|

|

Maximum capacity |

Highest limit of specified measuring range |

Emax |

125 |

500, 1,000, 2,000 |

kg |

|

|

Safe load limit |

Maximum load without irreversible damage |

Elim |

150 |

|

% Emax |

|

|

Destructive load |

Danger of mechanical destruction |

Ed |

>300 |

|

% Emax |

|

|

Max. permissible lifting force |

To still hold the specified performance afterwards |

|

100 |

|

% Emax |

|

|

Destructive lifting force |

Danger of mechanical destruction (by lifting) |

|

>300 but max. 3 |

t |

% Emax |

|

|

(Nominal) side force range |

Range of side force to hold the specified performance |

QKn |

<20 |

|

% load |

|

|

Side force limit |

Maximum side force without irreversible damage |

Elq |

For 125 kg: 200 For 250/500 kg: 150 For 1 t, 2 t: 100 (max. 1 t) |

% Emax |

||

|

Minimum LC verification |

Minimum load cell verification interval vmin = Emax /Y |

Y |

5,000 |

14,000 |

||

|

Deadload output return |

Factor for dead load output return after load (DR=½*Emax/Z) |

Z |

1,000 |

3,000 |

|

|

|

Rated output |

Relative output at maximum capacity |

Cn |

2 |

|

mV/V |

|

|

Tolerance on rated output |

Permissible deviation from rated output |

dc |

<0.25 |

<0.07 |

% Cn |

|

|

Zero output signal |

Load cell output signal under unloaded condition |

Smin |

0 ± 2.0 |

0 ± 1.5 |

% Cn |

|

|

Repeatability error |

Max. change in load cell output for repeated loading |

εR |

<0.01 |

<0.005 |

% Cn |

|

|

Creep, during 30 min |

max.change in load cell output under Emax |

dcr |

<0.03 |

<0.016 |

% Cn |

|

|

Non-linearity |

Max. deviation from best straight line through zero |

dLin |

<0.035 |

<0.01 |

% Cn |

|

|

Hysteresis |

Max. difference in LC output between loading and unloading |

dhy |

<0.035 |

<0.016 |

% Cn |

|

|

Temperature effect (TK) on Smin |

Max. change of Smin over BT |

TKSmin |

<0.028 |

<0.01 |

% Cn/10K |

|

|

Temperature effect on C1) |

Max. change of C over BT |

TKC |

<0.03 |

<0.01 |

% Cn/10K |

|

|

Input impedance |

Between supply terminals |

RLC |

1,080 ± 10 |

|

Ω |

|

|

Output impedance |

Between measuring terminals |

RO |

1,010 ± 1 |

|

Ω |

|

|

Insulation impedance |

Between measuring circuit and housing at 100 VDC |

RIS |

>5,000 |

|

MΩ |

|

|

Insulation voltage |

Between circuit and housing (Novego® ..E only) |

|

500 |

|

VDC |

|

|

Recommended supply voltage |

To hold the specified performance |

Bu |

4 to 20 |

|

VDC |

|

|

Max. supply voltage |

Permissible for continuous operation without damage |

Umax |

24 |

|

VDC |

|

|

Nominal ambient temp. range |

To hold the specified performance |

BT |

-10 to +40 |

|

°C |

|

|

Usable ambient temp. range |

Permissible for continuous operation without damage |

BTu |

-30 to +95 |

|

°C |

|

|

Storage temperature range |

Transportation and storage |

BTi |

-40 to +95 |

|

°C |

|

|

Permissible eccentricity |

Permissible displacement from nominal load line |

Sex |

±2.5 |

|

mm |

|

|

Vibration resistance |

Resistance against oscillations (IEC 68-2-6 Fc) |

|

20 g, 100 h, 10 |

to 150 Hz |

||

|

Air pressure effect |

Influence of ambient air pressure on Smin |

PKSmin |

<17 |

|

g/kPa |

|

|

Nominal deflection Material (sensor) Material (pendulum base) Protection class

Cables

Cable bending radius |

Max. elastic deformation under nominal load For Emax ≤ 500 kg Snom Max. 0.1 mm For Emax ≥ 1 Max. 0.2 1.4418 (DIN EN 10088-3) 1.4301 and 1.4418 (DIN EN 10088-3) according IEC 529 – Novego®: IP66 / IP68* / IP69 – Connexx®: IP66 / IP 68** TPE colour: grey, length: 5 m, ø 5 mm, 4 x 0.35 mm2

Novego® ..E TPE, colour: blue, length: 5 m, ø 5 mm, 4 x 0.35 mm2 ≥25 mm in case of fixed installation ≥75 mm in case of flexible installation |

|||||

Everything you need for easy installation, built-in: mounting kit with height

adjuster and tilt correction

Novego® offers innovative features for the food industry that ensure simple, error-free installation. By choosing this weighing module, you are opting for rapid, precise, hygienic assembly, and save yourself additional, time-consuming constrainer alignment.

| Weighing module Novego® product configuration | ||||

| Adapter plate |  |

|

|

|

| Novego®/00S | Novego®/00S | Novego®/00S | Novego®/01S | |

| Load cell |  |

|

|

|

| Novego® 125 2.000 kg C3 | Novego® 125 2.000 kg C3 | Novego® 125 2.000 kg C3 | Novego® 125 2.000 kg C3 | |

| Pendulum base |  |

|

|

|

| Novego®/02S rack-mounted | Novego®/03S floor-mounted | Novego®/04S tilt correction for floor mounting | Novego®/04S tilt correction for floor mounting | |

| Error-free installation and exceptional corrosion resistance | ||

|

Simple installation without time-consuming constrainer alignment: the built-in |

The stainless steel 1.4418 used to make the Novego® has a maximum |

|

Protection classes IP68 and IP69, in accordance with DIN EN 60529. The load cell can be submerged in water to a depth of 1.5 m for 10,000 hours, and is spray-proof. The weighing module is suitable for explosion sub-group IIC. Designation of the load cell for potentially explosive atmospheres

| Zone | Designation | Certificate no. | For |

| 0 and 1 | II1G Ex ia IIC T6 Ga Ex ia IIC T6 Ga 0Ex ia IIC T6 (“) | BVS 16 ATEX E 005 IECEx BVS 16.0005 | Only PR 6261/..E (Novego® ..E) |

| 20 and 21 | II 1D Ex ta IIICT160°C Da Ex ta IIIC T160 °C Da Ex ta IIIC T160 °C X (“) | TÜV 03 ATEX 2301 X IECEx TUN 17.0025X | all PR 6261 (Novego®) |

| 2 | II 3G Ex nA IIC T6 Gc 2Ex nA IICT6X (“) | Manufacturer’s declaration | All PR 6261 (Novego®) |

| 22 | II 3D Ex tc IIIC T85 °C Dc Ex tc IIIC T85 °C X (“) | Manufacturer’s declaration | All PR 6261 (Novego®) |

| Ambient temperature in Ex-Area -30… +55 °C | |||

| (“) only with approval TP TC 012 (TRCU 012) -52…+55 °C | |||

| FMus | IS CL I, II, II, DIV 1, GP A, B, C, D, E, F, G Entity – 4012 101 5688 NI CL I, II, II, DIV 2, GP A, B, C, D, E, F, G NIFW – 4012 101 5688 T4A Ta= -40 °C bis 70 °C; T5 Ta= -40 °C bis 55 °C | FM17US0276 | All PR 6261 (Novego®) |

| FMca | IS CL I, II, II, DIV 1, GP A, B, C, D, E, F, G Entity – 4012 101 5688 NI CL I, II, II, DIV 2, GP A, B, C, D, E, F, G NIFW – 4012 101 5688 T4A Ta= -40 °C bis 70 °C; T5 Ta= -40 °C bis 55 °C | FM17CA0138 | All PR 6261 (Novego®) |

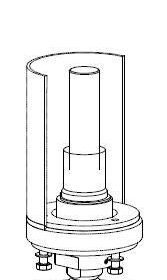

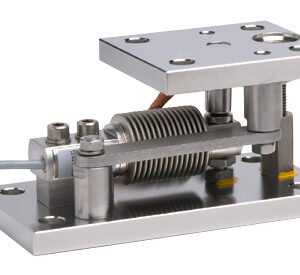

Fitted with the converter Connexx®, the load cell Novego® offers a whole host of possibilities:

- The digital version guarantees fast signalling times for reliable dosing processes.

- Thanks to the use of field bus communication, the cable junction box is no longer needed.

- The standard interface CANopen ensures straightforward installation and calibration.

- CANopen allows for extra-long communication paths of up to 200 m.

- Weight values can also be generated individually – per load cell – meaning that defective load cells can be identified more easily.

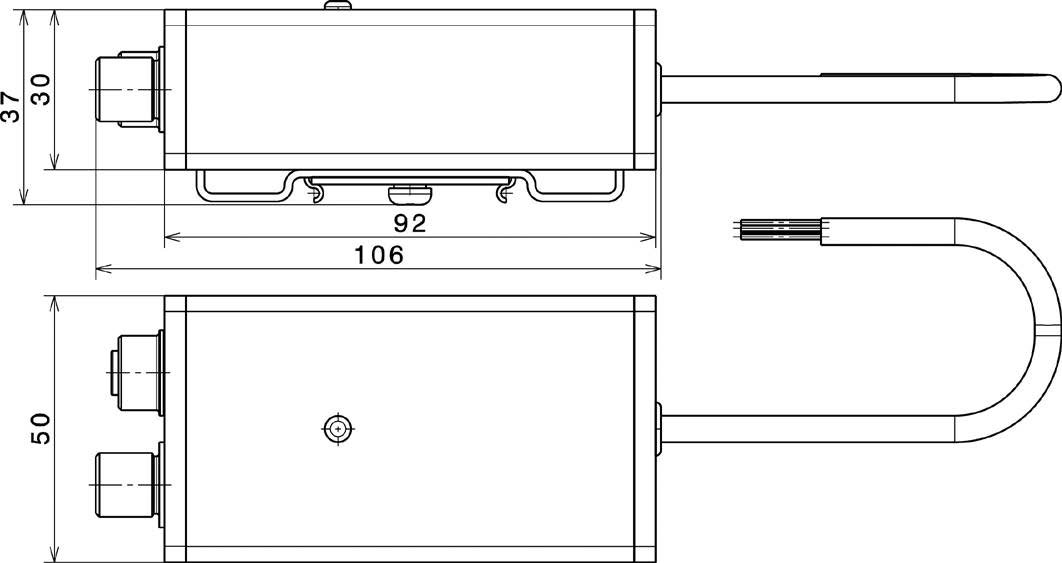

Converter Connexx®

| Parameter | Description | Abbr. | C3* | Unit |

| Nominal ambient temp. range | To hold the specified performance | BT | -10 … +40 | °C |

| Usable temperature range | Permissible for continuous operation without damage | BTu | -30 … +60 | °C |

| Storage temperature range | Without electrical and mechanical stress | BTi | -30 … +70 | °C |

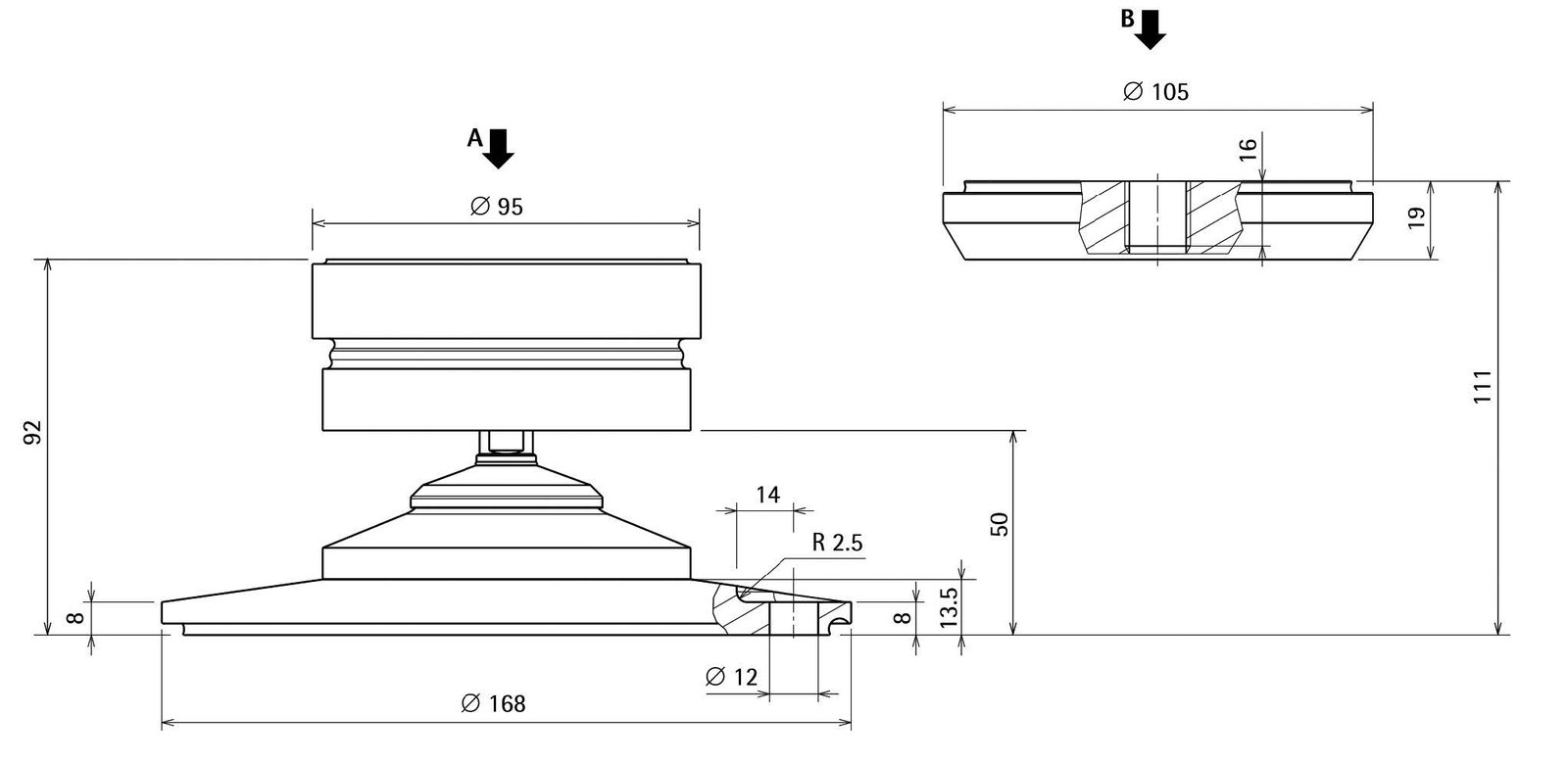

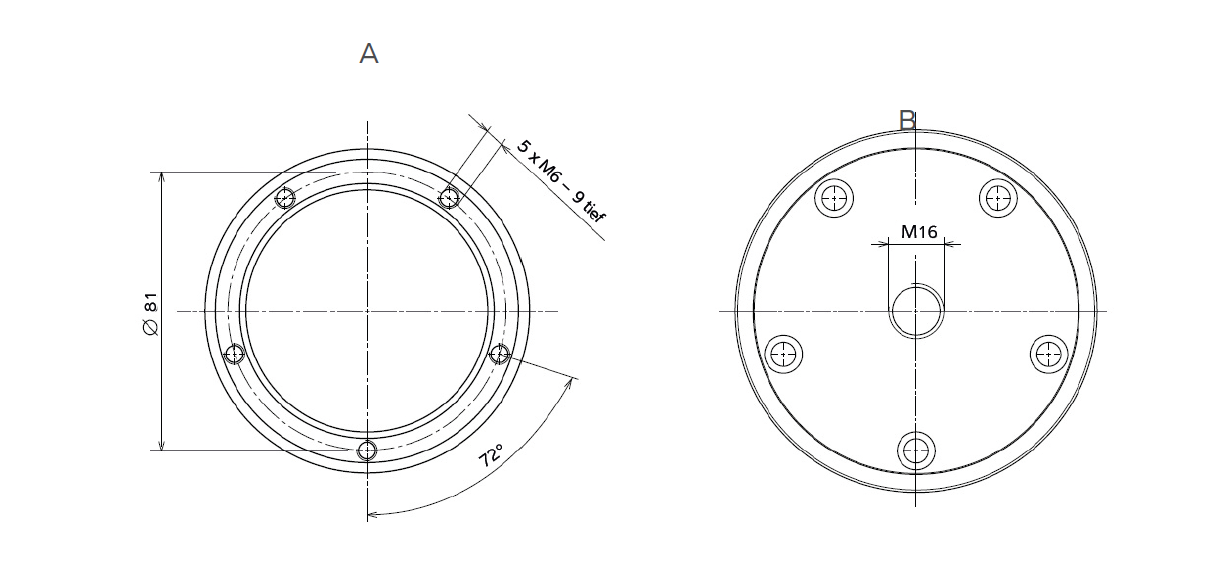

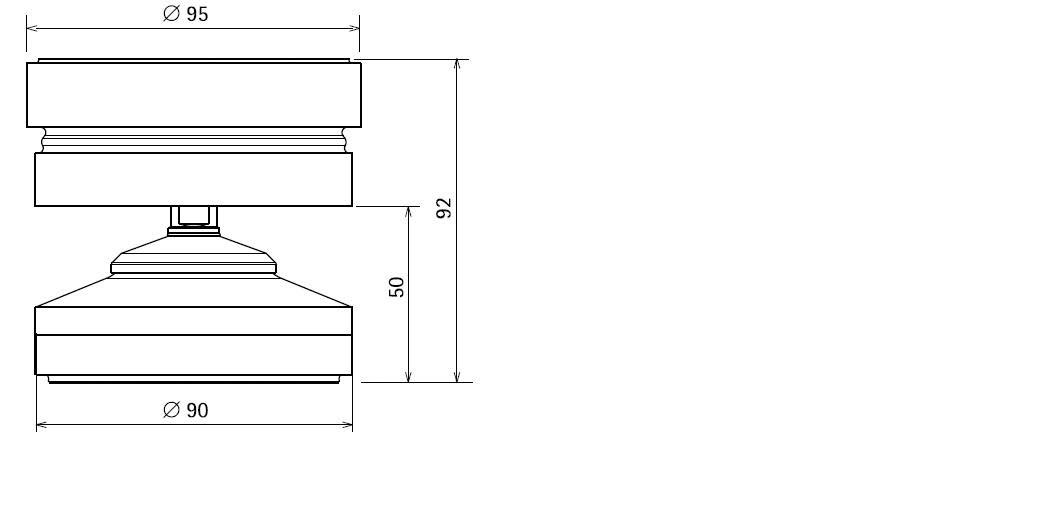

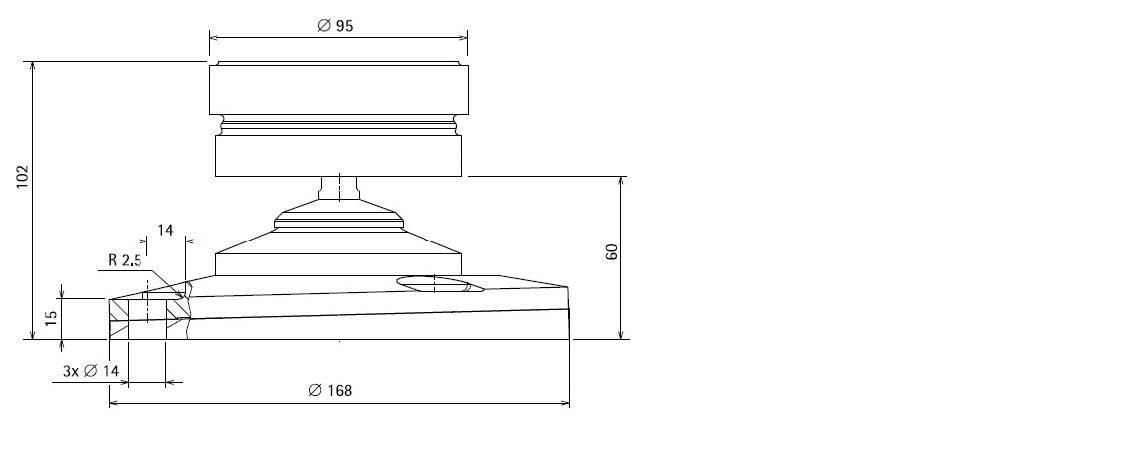

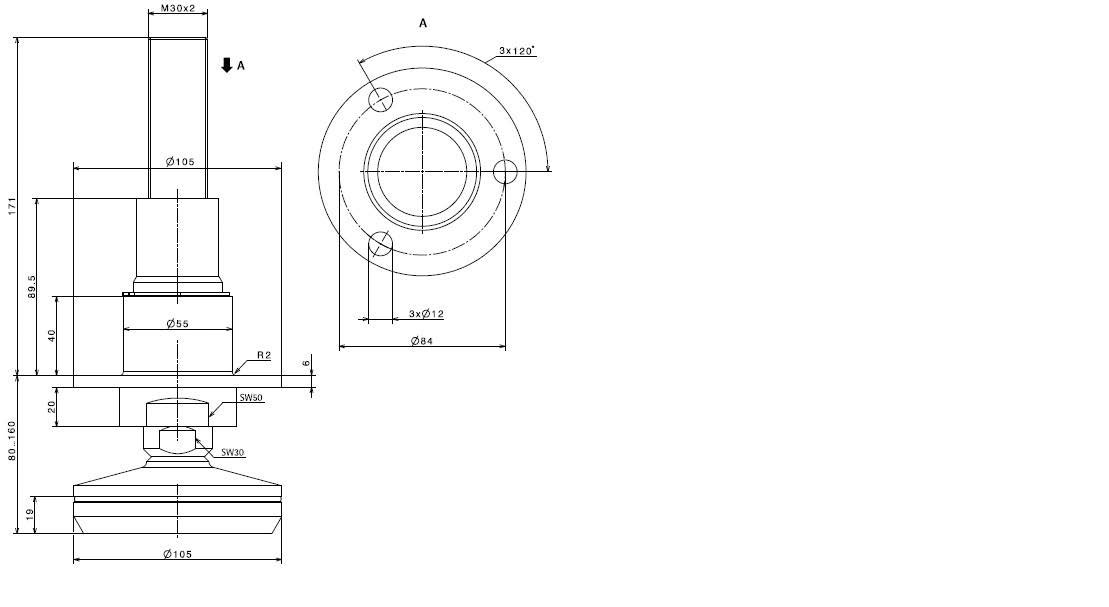

All dimensiones in mm

Technical drawings

Built-in tilt correction and height adjuster

Built-in tilt correction for sloped surfaces with a gradient of up to 3°

Built-in height adjuster to balance out vessel feet

Dimensions of the load cell Novego®, pendulum base for floor mounting Novego®/03S and adapter plate Novego®/00S

Drilling pattern for load cell Novego® and adapter plate Novego®/00S

Dimensions of the load cell Novego® and pendulum base for rack mounting Novego®/02S

All dimensiones in mm

Dimensions of the load cell Novego® and pendulum base with tilt correction for floor mounting Novego®/04S

Dimensions and drilling pattern for height adjuster Novego®/01S

Dimensions and drilling pattern for height adjuster Novego®/01S

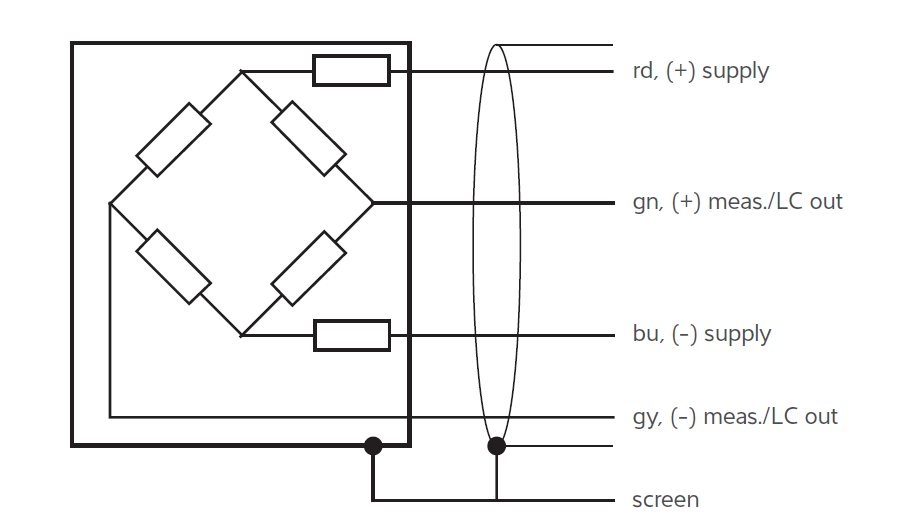

Connection diagram All dimensiones in mm

| Weighing module Novego® | ||||

| Type | Packaging (mm) | Weight gross/net (kg) | Order number | Converter Connexx® (optional) |

| PR 6261/125 kg D1 | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940526101112 | ● |

| PR 6261/125 kg C3 | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940526103112 | ● |

| PR 6261/250 kg C3 | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940526103125 | ● |

| PR 6261/500 kg C3 | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940526103150 | ● |

| PR 6261/1t C3 | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940526103210 | ● |

| PR 6261/2t C3 | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940526103220 | ● |

| Weighing module Novego® as ex-version | |||

| Type | Packaging (mm) | Weight gross/net (kg) | Order number |

| PR 6261/125 kg D1E | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940566101112 |

| PR 6261/125 kg C3E | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940566103112 |

| PR 6261/250 kg C3E | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940566103125 |

| PR 6261/500 kg C3E | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940566103150 |

| PR 6261/1t C3E | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940566103210 |

| PR 6261/2t C3E | ca. 290 × 210 × 120 | ca. 1.7/ca. 1.4 | 940566103220 |

| Mounting parts weighing module Novego® | |||||

| Type | Description | Packaging (mm) | Weight gross/net (kg) | Order number | |

| Pendulum | PR 6061/02S | Pendulum base for rack mounting | ca. 255 × 255 × 65 | ca. 1.8/1.3 | 940536061022 |

| PR 6061/03S | Pendulum base for floor mounting | ca. 255 × 255 × 65 | ca. 2.9/2.5 | 940536061032 | |

| PR 6061/04S | Pendulum base for floor mounting with built-in tilt correction | ca. 255 × 255 × 65 | ca. 4.8/4.2 | 940536061042 | |

| Adapter plate | PR 6061/00S | Adapter plate with threaded bolts | ca. 147 × 125 × 50 | ca. 1.2/1.1 | 940536061002 |

| PR 6061/01S | Adapter plate with built-in height adjuster | ca. 425 × 105 × 100 | ca. 3.7/3.3 | 940536061012 | |

| PR 6061/05S | Shim set | ca. 200 × 130 × 40 | ca. 1.6/1.4 | 940536061052 | |

| PR 6061/06S | Transport and assembling Kit | ca. 190 × 140 × 40 | ca. 0.3/0.2 | 940536061062 | |

| PR 6061/07S | Pivot | ca. 290 × 210 × 120 | ca. 2.6/2.2 | 940536061072 | |

| Accessoires weighing module Novego® | ||||

| Type | Description | Packaging (mm) | Weight gross/ net (kg) | |

| PR 6130/64Sa | Cable junction box for use in potentially explosive atmospheres | Material: stainless steel 1.4301, IP68, IP69 for all industrial, intrinsically safe and verifiable applications, for up to 4 load cells | 190 × 160 × 60 mm | ca. 1.4/ca. 1.2 |

| PR 6130/65S | Cable junction box for use in potentially explosive atmospheres | Material: rust-proof stainless steel 1.4301, IP68, IP69 for all industrial, intrinsically safe and verifiable applications, for up to 4 load cells | 172 × 105 × 55 mm | ca. 1.0/ca. 0.75 |

| PR 6130/34Sa | Cable junction box | Material: rust-proof stainless steel 1.4301, IP68, IP69 for all industrial, verifiable applications, for up to 4 load cells | 190 × 160 × 60 mm | ca. 1.3/ca. 1.0 |

| PR 6130/35S | Cable junction box | Material: rust-proof stainless steel 1.4301, IP68, IP69 for all industrial, verifiable applications, for up to 4 load cells | 172 × 105 × 55 mm | ca. 0.8/ca. 0.6 |

| PR 6135 | Installation cable | For all applications, grey | D = 9 mm | |

| PR 6135/A | Installation cable, reinforced | For all applications, grey | D = 13 mm | |

| PR 6136 | Installation cable | For all intrinsically safe applications, blue | D = 11 mm | |

| PR 6136/A | Installation cable, reinforced | For all intrinsically safe applications, blue | D = 13 mm | |

Ordering information

| Converter Connexx® | ||

| Type | Description | Order number |

| PR 6261/DIGITAL KIT | The converter Connexx® can only be ordered with the above-mentioned load cells from the PR 6261 series. When ordering, both order numbers need to be given. | 940516100000 |

Additional information: The converters Connexx® can be used with the Indicator X3. To do this, the indicator X3 must be equipped with a CANopen interface card PR 5510/05 (940535510051).

| Converter Connexx® – application sets | ||

| Type | Description | Order number |

| PR 6154/03 | Application set for 3 load cells. Includes: 2 × PR 6155/05, 1 × PR 6152/25, 1 × PR 6153/99 | 940536154031 |

| PR 6154/04 | Application set for 4 load cells. Includes: 3 × PR 6155/05, 1 × PR 6152/25, 1 × PR 6153/99 | 940536154041 |

| Converter Connexx® – load cell accessories | ||

| Type | Description | Order number |

| PR 6152/10 | Connection cable between Connexx® and X3 (10 m) | 940536152101 |

| PR 6152/25 | Connection cable between Connexx® and X3 (25 m) | 940536152251 |

| PR 6152/40 | Connection cable between Connexx® and X3 (40 m) | 940536152401 |

| PR 6153/98 | Divided cable gland | 940536153981 |

| PR 6153/99 | Terminal resistor for Connexx®, M12 | 940536153991 |

| PR 6155/05 | Connection cable between Connexx® and Connexx® (5 m) | 940536155051 |

| PR 6155/10 | Connection cable between Connexx® and Connexx® (10 m) | 940536155101 |

상품평

아직 상품평이 없습니다.