설명

SLB215 Beam Load Cells

The SLB215 is approved for use in various applica-tions in Europe, Asia, America and almost everywhere else in the world. If an approval is required, the SLB215 probably already complies.

Floor Scales

Use the SLB215 load cell in platform and floor scales. With threaded load-introduction hole, the load cell can

be used with a threaded foot for easy levelling. Due to the hermetic welded design reliability in most industrial en-vironments is guaranteed. The full set of approvals provides maximum applica-bility and safety in these applications.

Tank Weighing

The capacity range from 220 kg to 4.4 t allows the weighing of tanks, hoppers and silos. Various accessories are available to ease installation and to ensure good performance

Hermetically Sealed

SLB215 load cells are made from nickel plated tool steel but are her-metically sealed, something normally available only on higher end stainless models. This protects the load cell from damp for the best stability and measu-ring performance.

Accessories

The optional accessories for proper load introduction guarantee the optimal performance in conjunction with thermal expansion and vibration.

SLB215 Load Cell Specifications

| Parameter | unit of measure | Specification | ||||||

| SLB215 | ||||||||

| Rated Capacity (R.C.) | kg (lb, nominal) | 110 (250) | 220 (500) | 550 (1250) | 1100 (2500) | 2200 (5000) | 4400 (10000) | |

| Rated Output | mV/V @R.C. – kg | 0.970 ± 0.002 | 1.940 ± 0.002 | |||||

| mV/V @R.C. – lb | 1.000 ± 0.002 | 2.000 ± 0.002 | ||||||

| Zero load Output | %R.C. | ≤ 1.0 | ||||||

| Combined Error 1 2 | %R.C. | ≤ 0.018 | ≤ 0.03 | |||||

| Repeatability Error | %A.L. (3) | ≤ 0.01 | ≤ 0.02 | |||||

| Creep, 30 minute | %A.L. | ≤ 0.0167 | ≤ 0.0167 | |||||

| Min. Dead Load Output Return (DR), 30 min | %A.L. | ≤0.0167 | ≤ 0.0167 | |||||

| Temperature Effect on | Min. Dead load Output | %R.C./°C (../°F) | ≤ 0.0023 (0.0013) | |||||

| Sensitivity 2 | %A.L./°C (../°F) | ≤ 0.0009 (0.0005) | ≤ 0.002 (0.001) | |||||

| Temperature Range | Compensated | °C (°F) | -10 ~ +40 (+14 ~ +104) | |||||

| Operating | °C (°F) | -40 ~ +65 (-40 ~ +150) | ||||||

| Safe Storage | °C (°F) | -40 ~ +80 (-40 ~ +176) | ||||||

| OIML / European Approval 4 | OIML Cert. No. | R60/2000-NL1-13.19 | ||||||

| European Cert. No. | TC8311 | |||||||

| Class | C3 | C1 | ||||||

| nmax | 3000 | 1000 | ||||||

| Y | 6000 | |||||||

| PLC | 0.7 | |||||||

| Humidity Symbol | None | |||||||

| Min. dead load | kg (lb) | 0.4 (0.88) | ||||||

| Z | 3000 | 1000 | ||||||

| NTEP Approval 4 | Number | 13-081 | ||||||

| Class | III M | |||||||

| nmax | 5000 | 1600 | ||||||

| Vmin | kg (lb) | 0.018 (0.04) | 0.037 (0.08) | 0.092 (0.20) | 0.183 (0.40) | 0.367 (0.81) | 0.73 (1.62) | |

| Min. dead load | kg (lb) | 0 (0) | ||||||

| ATEX Approval 4 | Number, cat. 2 | DEKRA 13ATEX0081 | ||||||

| Number, cat. 3 | DEKRA 13ATEX0082 | |||||||

| Rating | II 2 G Ex ib IIC T4 Gb | |||||||

| II 2 D Ex ib IIIC T100°C Db | ||||||||

| II 3 G Ex ic IIC T4 Gc | ||||||||

| II 3 G Ex nA IIC T4 Gc | ||||||||

| II 3 D Ex tc IIIC T100°C Dc | ||||||||

| Ta: -40°C to +60°C | ||||||||

| Entity Parameters | Ui=20V, Ii=600mA, Pi=1.25W, Ci=0.2nF/m (5), Li=1µH/m (5) | |||||||

| IECEx Approval 4 | Number | IECEx DEK 20.0086X | ||||||

| Rating | Ex ib IIC T4 Gb; Ex ic IIC T4 Gc; Ex ec IIC T4 Gc | |||||||

| Ex ib IIIC T100 °C Db; Ex tc IIIC T100 °C Dc | ||||||||

| Entity Parameters | Ui=20V, Ii=600mA, Pi=1.25W, Ci=1.2nF, Li=6µH; Urated = 20V, Irated = 55mA | |||||||

| Factory Mutual Approval US/Canada 4 | Number, USA / Canada | FM18US0025 / FM18CA0032 | ||||||

| Rating USA | IS / I, II, III / 1 / ABCDEFG / T4 Entity | |||||||

| NI / I / 2 / ABCD / T6 NIFW; S / II, III / 2 / FG / T6 | ||||||||

| Rating Canada | IS / I, II, III / 1 / ABCDEFG / T4 Entity | |||||||

| NI / I / 2 / ABCD / T6 NIFW; DIP / II, III / 2 / FG / T6 | ||||||||

| Entity Parameters | Vmax=20V, Imax=600mA, Pi=1.25W, Ci=0, Li=0; NIFW: Vmax=20V, Imax=600mA, Ci= 0, Li=0 | |||||||

| System Drawing No, USA | 30032271 | |||||||

| Excitation Voltage | Recommended | V DC | 5~15 | |||||

| Max. | 20 | |||||||

| Terminal Resistance | Excitation | Ω | 350±4 | |||||

| Output | 350±1 | |||||||

| Insulation Resistance @50VDC | MΩ | >5000 | ||||||

| Breakdown Voltage | V AC | >500 | ||||||

| Material | Spring Element | Alloy Steel | ||||||

| Enclosure | 304 stainless steel | |||||||

| Cable entry fitting | 304 stainless steel | |||||||

| Cable | PVC | |||||||

| Finish | Nickel plated | |||||||

| Protection | Type | Welded | ||||||

| IP Rating | IP67 | |||||||

| NEMA Rating | NEMA 6 | |||||||

| Load Limit | Safe | %R.C. | 150 | |||||

| Ultimate | 300 | |||||||

| Safe Side Load | %R.C. | 100 | ||||||

| Safe Dynamic Load | %R.C. | 70 | ||||||

| Fatigue Life | cycles @R.C. | > 1,000,000 | ||||||

| Direction of Loading | Beam | |||||||

| Deflection @ R.C., nominal | mm (in) | 0.07 (0.003) | 0.14 (0.005) | 0.23 (0.009) | 0.26 (0.01) | 0.37 (0.015) | 0.6 (0.024) | |

| Weight, nominal | kg (lb) | 1 (2.2) | 1.4 (3.1) | 2.4 (5.3) | ||||

| Cable | Length | m (ft) | 5, 10 (16.4, 32.8) | |||||

| Diameter | mm (in) | 5.2 (0.20) | ||||||

| Barometric Pressure Effect on Zero Load Output | kg/kPa (lb/in.Hg) | None | ||||||

| Overload Protection | Yes | No | ||||||

| Mounting Screw | Grade | 10.9 (Grade 8) | ||||||

| Size/thread | mm (in) | M12 (1/2-13 UNC) | M20 (3/4-10 UNC) | |||||

| Engaged Length | mm (in) | – | ||||||

| Torque, nominal | N.m (ft-lb) | 98 (82) | 330 (190) M18: 275 (158) | |||||

| Drawing No. | Dimensions | 30076301 | ||||||

| 2D | 30094485 | |||||||

| 3D | 30094486 | |||||||

1) Error due to the combined effect of non-linearity and hysteresis

2) Typical values only. The sum of errors due to combined error and temperature effect on sensitivity comply with the requirements of OIML R60 and NIST HB44

3) A.L. = Applied Load

4) See certificate for complete information.

5) /m Load cell cable

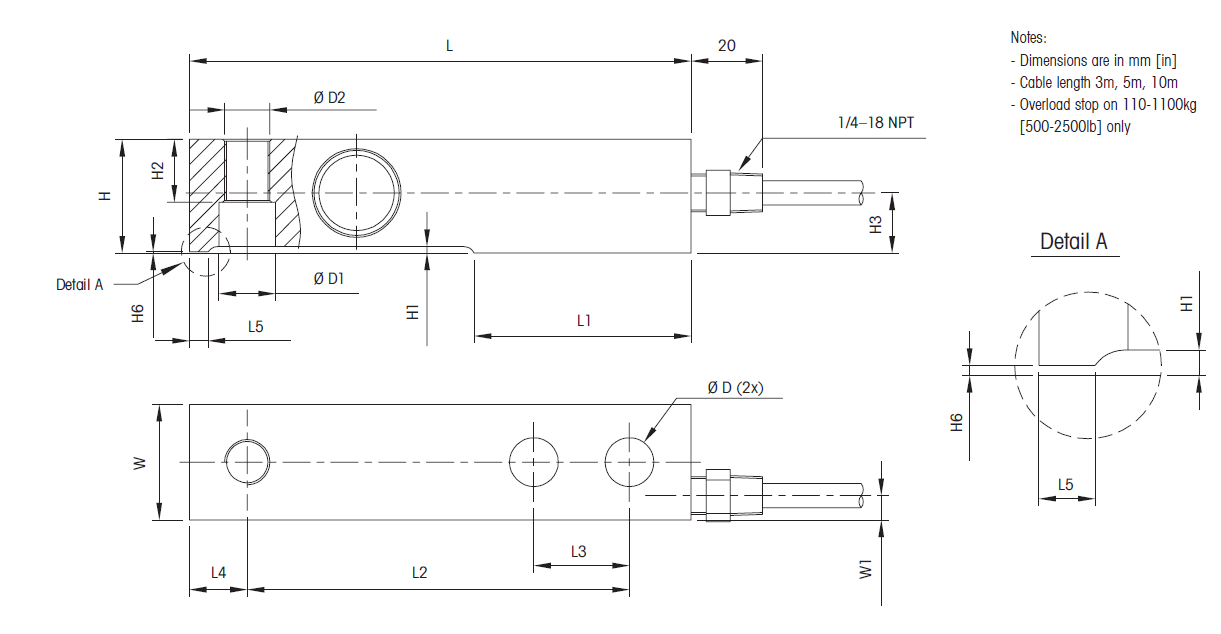

SLB215 Load Cell Dimensional Drawings mm [in]

Dimensions and locations

| Parameter | SLB215 (110-1100 kg) | SLB215 (2200 kg) | SLB215 (4400 kg) |

| Capacity | 110-1100 kg [250lb-2500lb] | 2200 kg [5000 lb] | 4400 kg [10 000 lb] |

| D (2x) | 13.0 [0.51] | 13.0 [0.51] | 20.5 [0.81] |

| D1 | 12.5 [0.49] | 12.5 [0.49] | 22.2 [0.87] |

| D2 | M12 | M12 | M20 |

| H | 30.2 [1.19] | 36.6 [1.44] | 42.9 [1.69] |

| H1 | 1.8 [0.07] | 2.6 [0.10] | 2.5 [0.10] |

| H2 | 20 [0.79] | 20 [0.79] | 20 [0.79] |

| H3 | 16.0 [0.63] | 19.6 [0.77] | 22.7 [0.89] |

| H6 | 0.48 [0.02] | 2.6 [0.10] | 2.5 [0.10] |

| L | 133.4 [5.25] | 136.7 [5.38] | 171.5 [6.75] |

| L1 | 56.5 [2.22] | 55.6 [2.19] | 73.8 [2.91] |

| L2 | 101.6 [4.00] | 101.6 [4.00] | 133.4 [5.25] |

| L3 | 25.4 [1.00] | 25.4 [1.00] | 38.1 [1.50] |

| L4 | 15.4 [0.61] | 18.4 [0.72] | 21.4 [0.84] |

| L5 | 6.4 [0.25] | ||

| W | 30.7 [1.21] | 36.8 [1.45] | 42.9 [1.69] |

| W1 | 6.5 [0.26] | 6.0 [0.24] | 6.0 [0.24] |

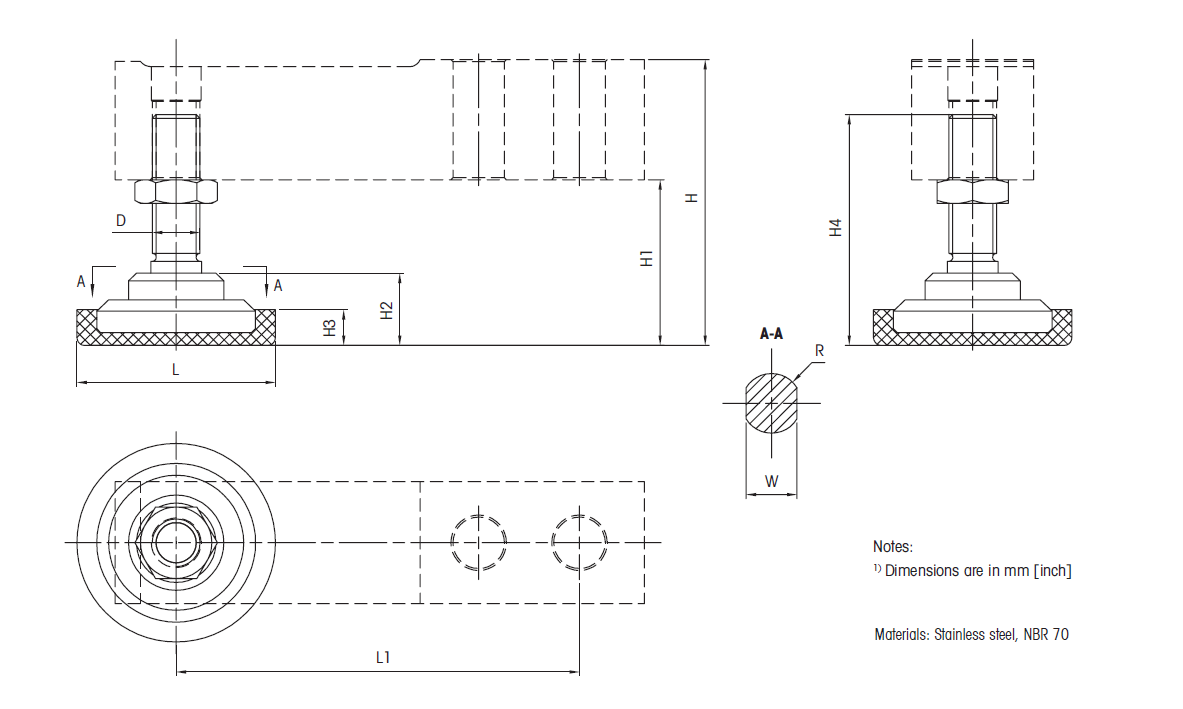

SLB215 Foot Kit FTKT mm [in]

Dimensions and locations

| Parameter | FTKT (110–1100 kg) | FTKT (2200 kg) | FTKT (4400 kg) |

| Capacity | 110–1100 kg [500–2500 lb] | 2200 kg [5000 lb] | 4400 kg [10 000 lb] |

| L | Ø50 [Ø1.97] | Ø50 [Ø1.97] | Ø70 [Ø2.76] |

| L1 | 101.6 [4.00] | 101.6 [4.00] | 133.4 [5.25] |

| D | M12 | M12 | M20 |

| H min. | 60 [2.36] | 66.4 [2.61] | 91 [3.58] |

| H max. | 72 [2.84] | 78.4 [3.09] | 110 [4.33] |

| H1 min. | 29.8 [1.17] | 29.8 [1.17] | 48.1 [1.89] |

| H1 max. | 41.8 [1.65] | 41.8 [1.65] | 67.1 [2.64] |

| H2 | 18.2 [0.72] | 18.2 [0.72] | 29.5 [1.16] |

| H3 | 9 [0.35] | 9 [0.35] | 17 [0.67] |

| H4 | 58.2 [2.29] | 58.2 [2.29] | 87.5 [3.44] |

| R | 7.5 [0.30] | 7.5 [0.30] | 10 [0.39] |

| W | 12.8 [0.50] | 12.8 [0.50] | 20.8 [0.82] |

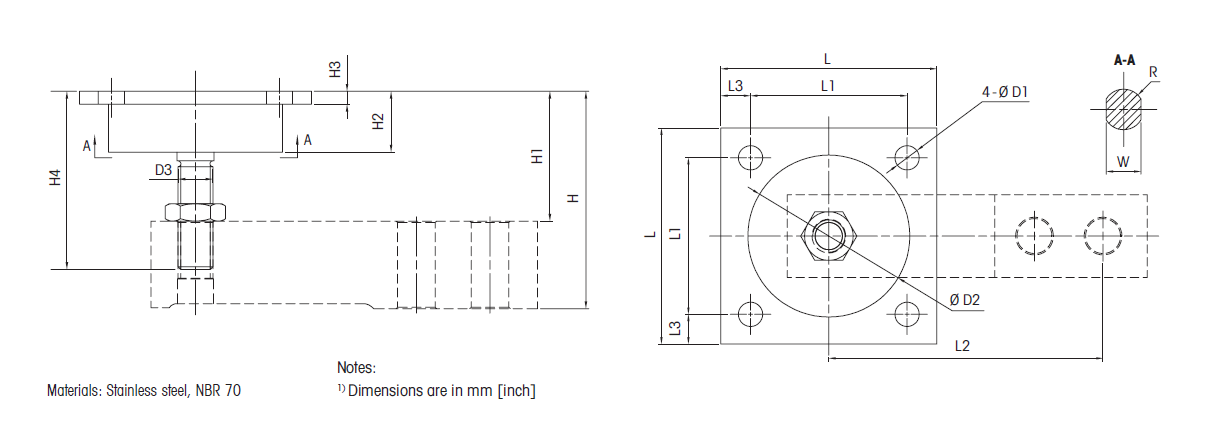

SLB215 Expansion and Vibration Kit EVKT mm [in]

Dimensions and locations

| Parameter | EVKT 110–1100 kg | EVKT 2200 kg | EVKT 4400 kg |

| Capacity | 110–1100 kg [500–2500 lb] | 2200 kg [5000 lb] | 4400 kg [10 000 lb] |

| D1 | Ø9 [Ø0.35] | Ø9 [Ø0.35] | Ø11 [Ø0.43] |

| D2 | Ø60 [Ø2.36] | Ø60 [Ø2.36] | Ø72 [Ø2.83] |

| D3 | M12 | M12 | M20 |

| H min. | 63 [2.48] | 69.4 [2.73] | 91 [3.58] |

| H max. | 75 [2.95] | 81.4 [3.21] | 110 [4.33] |

| H1 min. | 32.8 [1.29] | 32.8 [1.29] | 48.1 [1.89] |

| H1 max. | 44.8 [1.76] | 44.8 [1.76] | 67.1 [2.64] |

| H2 | 21.5 [0.85] | 21.5 [0.85] | 29.5 [1.16] |

| H3 | 4.5 [0.18] | 4.5 [0.18] | 9.5 [0.37] |

| H4 | 61.5 [2.42] | 61.5 [2.42] | 87.5 [3.44] |

| L | 80 [3.15] | 80 [3.15] | 100 [3.94] |

| L1 | 58 [2.28] | 58 [2.28] | 76 [2.99] |

| L2 | 101.6 [4.00] | 101.6 [4.00] | 133.4 [5.25] |

| L3 | 11 [0.43] | 11 [0.43] | 12 [0.47] |

| R | 7.5 [0.30] | 7.5 [0.30] | 10 [0.39] |

| W | 12.8 [0.50] | 12.8 [0.50] | 20.8 [0.82] |

| S HMAX* | ±3 [±0.12] | ±3 [±0.12] | ±3 [±0.12] |

| SVMAX** | 1 [0.04] | 1.6 [0.07] | 2.2 [0.09] |

| Max. Side load ratings | 2100 N | 2400 N | 2800 N |

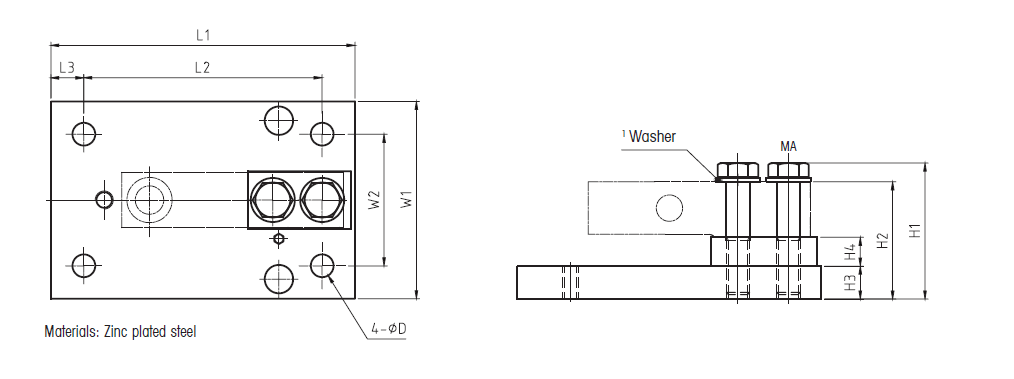

SLB215 Base Plate Kit BPK mm [in]

| Parameter | 110 kg–1.1 t [250–2500 lb] |

2.2 t [5000 lb] |

4.4 t [10,000 lb] |

| L1 | 177.9 [7.00] | 12.7 [0.50] | 235.0 [9.25] |

| L2 | 184.2 [7.25] | ||

| L3 | 12.7 [0.50] | 12.7 [0.50] | 25.4 [1.00] |

| W1 | 152.4 [6.00] | ||

| W2 | 114.4 [4.50] | 152.4 [6.00] | 101.6 [4.00] |

| H1 | 89.0 [3.50] | 101.6 [4.00] | 105.0 [4.13] |

| H2 | 72.6 [2.86] | 105.0 [4.13] | 90.5 [3.56] |

| H3 | 65.1 [2.56] | 65.1 [2.56] | 25.4 [1.00] |

| H4 | 19.1 [0.75] | 19.1 [0.75] | 22.2 [0.87] |

| D | 15.88 [0.625] | 12.7 [0.50] | 17.5 [0.69] |

| 2 MACS | 11.2 [0.44] | 11.2 [0.44] | 270 Nm [200 lb–ft] |

| 3 MASS | 98 Nm [72 lb–ft] | 98 Nm [72 lb–ft] | 270 Nm [200 lb–ft] |

1 Two washers only for 4.4t

2 Torque carbon steel version

3 Torque stainless steel version

SLB215 Load Cell Order Information

| Order Information | Description | Item No. |

|---|---|---|

| Load cell, model no. | SLB215-110kg (250lb) C3 5m (16.4ft) Ex | 30328249 |

| Load cell, model no. | SLB215-110kg (250lb) C3 10m (32.8ft) Ex | 30328250 |

| Load cell, model no. | SLB215-220kg (500lb) C3 5m (16.4ft) Ex | 72258650 |

| Load cell, model no. | SLB215-220kg (500lb) C3 10m (32.8ft) Ex | 72258654 |

| Load cell, model no. | SLB215-550kg (1250lb) C3 5m (16.4ft) Ex | 72258656 |

| Load cell, model no. | SLB215-550kg (1250lb) C3 10m (32.8ft) Ex | 72258660 |

| Load cell, model no. | SLB215-1.1t (2500lb) C3 5m (16.4ft) Ex | 72258693 |

| Load cell, model no. | SLB215-1.1t (2500lb) C3 10m (32.8ft) Ex | 72258697 |

| Load cell, model no. | SLB215-2.2t (5000lb) C3 5m (16.4ft) Ex | 72258699 |

| Load cell, model no. | SLB215-2.2t (5000lb) C3 10m (32.8ft) Ex | 72258703 |

| Load cell, model no. | SLB215-4.4t (10000lb) C1 5m (16.4ft) Ex | 72258710 |

| Load cell, model no. | SLB215-4.4t (10000lb) C1 10m (32.8ft) Ex | 72258714 |

| Options | Description | Item No. |

|---|---|---|

| Base Plate Kit BPK | Carbon Steel 110kg-1.1t (250-2500lb) | 30265369 |

| Base Plate Kit BPK | Carbon Steel 2.2t (5000lb) | 30265371 |

| Base Plate Kit BPK | Carbon Steel 4.4t (1000lb) | 30265373 |

| Expansion+Vibr Kit EVKT | Stainless Steel 110kg-2.2t (500-5000lb) | 30076302 |

| Expansion+Vibr Kit EVKT | Stainless Steel 4.4t (10000lb) | 30076303 |

| Foot Kit FTKT | Stainless Steel 110kg-2.2t (500-5000lb) | 30076304 |

| Foot Kit FTKT | Stainless Steel 4.4t (10000lb) | 30076305 |

SLB215 Load Cell Cable Colours

| Colour | Function |

| Green | + Excitation |

| Black | – Excitation |

| White | + Signal |

| Red | – Signal |

| Yellow | Shield* |

Weighing Electronics

METTLER TOLEDO offers a complete family of electronics from simple weighing to application solutions for filling, stock control, batching, formulation, counting, checkweighing.

Global Approvals

The SLB215 is provided with all listed approvals. No need to think about options and additional charges. Simplifies the conduct of global business, order processing and service-part stocking

상품평

아직 상품평이 없습니다.