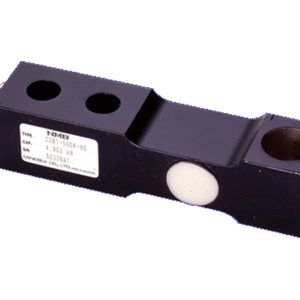

설명

Weighbeam DMR 15t

APPLICATION

- Railway scales

- Crane scales

- Coil scales

EQUIPMENT

- Two-line load introduction and outlet

- Stainless steel

- Hermetically sealed

FUNCTION

- High repeatability

- High long-term stability and consistently high accuracy

- No additional tie-rods or hold-downs

- Optional execution with two measuring circuits inside one sensor available

Mounting Dimensions

Technical Data

| DMR 15 t | Ref. | |||

| Rated capacity | Emax | 15 t | ||

| Accuracy class | C1 (OIML R60)

C2 upon request |

0.1 | ||

| Number of increments | nLC | 1000 | ||

| Nominal measuring range | Bmax | Bmax = Emax | ||

| Sensitivity | Cn | 2.00 mV/V | ||

| Combined error | Fcomb | + 0.06 % | + 0.1 % | Cn |

| Return of minimum preload signal | dDR | + 0.033 % | Cn | |

| Creep error (30 min) | dcr | + 0.049 % | + 0.05 % | Cn |

| Zero signal temperature coefficient | TKsmin | + 0.028 % / 10K | Cn | |

| Sensitivity temperature coefficient | TKc | + 0.023 % / 10K | ||

| Minimum increment value | v min | Emax / 5000 | — | |

| Minimum measuring range | Bmin | 33.3 % | — | |

| Limit load (with LQ = 0.15 x Emax) | LL | 26 t | ||

| Rupture load (with LQ = 0.15 x Emax) | LB | 38 t | ||

| Max. lateral load | LQ | 13 t | ||

| Input resistance | RLC | 378 + 3 ohms | tref | |

| Output resistance | Ro | 360 + 0.5 ohms | tref | |

| Zero signal | So | + 1% | Cn | |

| Relative sensitivity deviation | dc | + 0.2% | Cn | |

| Supply voltage nominal range | BU | 5 V to 12 V | ||

| Nominal temperature range | BT | -10°C to +40°C | ||

| Service temperature range | Btu | -30°C to +120°C | ||

| Reference temperature | tref | 22°C | ||

| Material | Stainless steel | |||

| Protected to | IP 67 (laser welded) | |||

| Corrosion protection | see resistance list DDP8 483 | |||

| Dead weight | me | 25 kg | ||

|

Measuring cable |

4 x 0.5 mm2

screened in pairs and external screening outer diameter 6.5 mm, Length 8 m Silicone, -30°C to +150°C |

|||

|

Colour code |

Black: Input +

Blue: Input – Red: Output + White: Output – Green-Yellow: screen |

|||

Connecting surface quality requirements

INSTALLATION REQUIREMENTS

- Material quality “A”: Usually construction steel of minimum quality S355 is used

- Plate thickness “B”: Depends on stiffness of total construction. Plate thickness of connecting surface must be at least 40 mm

- Surface quality “C”: Required mean roughness of the connecting surfaces is 6.3 μm

- Planeness “D”: Maximum admissible planeness tolerance within each connecting surface is 0.05 mm

- Angular deviation to vertical axis “E”: Angle deviation of connecting surface to the vertical axis in both planes must not exceed ±2°

- Plane parallelism “F”: Upper and lower connecting surfaces to the weighbeam must be plane-parallel to within 0.1 mm

| Variant | Order No. |

| DMR 15 t 0.1 | V 000 522 .B01 |

| DMR 15 t C1 | upon request |

| DMR 15 t C2 | upon request |

| DMR 15 t

2 channels |

upon request |

상품평

아직 상품평이 없습니다.