설명

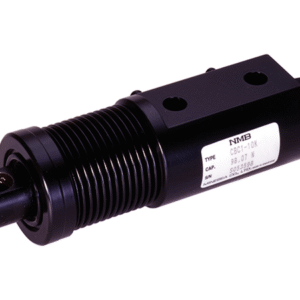

Weighbeam DWR 50 … 70 t

Application

- Scrap bucket, roller table weighing and tundish scales

- Silo and hopper scales

- Crane scales

Construction

- Rugged design, low headroom

- Plug-in connector

- High-grade stainless steel

Function

- Simple and economical installa- tion through direct screwing to the connecting structure without mov- able parts

- No need for additional tie-rods and hold-downs

- High long-term stability

- High degree of repeatability

- Separate mounting of weigh- beam and connecting cable possible

- Easy cable exchange

Operating principle (application tundish scale)

Technical Data

| DWR 50 t | DWR 60 t | DWR 70 t | Reference | |||||

| Rated capacity | Emax | 50 t | 60 t | 70 t | ||||

| Limit load

= Maximum admissible load |

LI | 100 t | 120 t | 140 t | ||||

| Rupture load | Ld | 150 t | 180 t | 210 t | ||||

| Max. admissible side load (with screw friction) | Lqmax | 5 t | 5 t | 5 t | ||||

| Max. admissible side load (with form fit) | Lqmax* | 35 t | 42 t | 49 t | ||||

| Sensitivity | Cn | 1,3 mV/V | 1,0 mV/V | 1,1 mV/V | Emax | |||

| Combined error | Fcomb | + 0,5% | Cn | |||||

| Creeping under load (30 min) | Fcr | + 0,05% | Cn | |||||

| Input resistance | Re | 380 W + 3 W | Tr | |||||

| Output resistance | Ra | 350 W + 2 W | Tr | |||||

| Reference supply voltage | Usref | 10V | ||||||

| Max. supply voltage | Usmax | 15V | ||||||

| Nominal temperature range | Btn | – 10°C to + 80°C | ||||||

| Service temperature range | Btu | – 15°C to + 120°C | ||||||

| Reference temperature | Tr. | + 22°C | ||||||

| Storage temperature range | BST | – 50°C to + 130°C | ||||||

| Temperature effect on zero signal | TKo | + 0,1% / 10K | Cn in Btn | |||||

| Temperature effect on sensitivity | TKc | + 0,07% / 10K | Cn in Btn | |||||

| Dead weight | me | 14 kg | 22 kg | 27 kg | ||||

| Corrosion protection | metallic bright, stainless | |||||||

| Protection class | IP 65 | |||||||

| Cable specification | Special silicone RAL 7000 (grey) Ø 6,5 mm x 15 m, – 30°C to + 150°C | |||||||

| Colour code | Black: Input + (82) Blue: Input – (81)

Red: Output + (28) White: Output – (27) Green-yellow: Screening |

|||||||

Mounting Dimensions

| Variante | A

mm |

B

mm |

C

mm |

D

mm |

E

mm |

F

mm |

G

mm |

H

mm |

J

mm |

K

mm |

L

mm |

M

mm |

N

mm |

| DWR 50 t | 230 | 88 | 67 | 190 | Ø 96,5 h12 | 80 | 3,15 | Ø 16,5 | 40 | Ø 100 | 36 | 35 | 57 |

| DWR 60 t | 284 | 132 | 112 | 240 | Ø 116 h13 | 90 | 4,15 | Ø 16,5 | 40 | Ø 120 | 36 | 38 | 76 |

| DWR 70 t | 330 | 146 | 127,8 | 290 | Ø 126 h13 | 96 | 4,15 | Ø 16,5 | 40 | Ø 130 | 40 | 43 | 85 |

Dimensions E and G for retaining ring DIN 471

Recommended tolerance of the bore (dimension K): F8

Connecting surface quality requirements

Material quality “A”

-

Usually construction steel of minimum quality S355 is used.

Plate thickness “B”

-

Depends on stiffness of total construction.

-

Plate thickness of connecting surface must be at least 40% of the weighbeam height (dimension F on page 3).

Surface quality “C”

-

Requisite mean roughness of the connecting surfaces is 6.3 µm.

-

Plane 1

-

Plane 2

Planeness “D”

-

Maximum admissible planeness tolerance within the two outer conjoint connecting surfaces for each weighbeam is 0.05 mm.

Angular deviation error to vertical axis “E”

-

Angle deviation of connecting surface to vertical axis in both planes of view must not exceed ± 2°.

Plane parallelism “F”

-

Upper and lower connecting surfaces to the weighbeam have to be plane parallel to minimum 0.1 mm.

-

Possibly execute load input convex (detail “X”).

-

Construction is angle compensating (also for elastic deflections).

| Variant | Order No. |

| DWR 50 t | V 013 257 .B04 |

| DWR 60 t | V 013 257 .B05 |

| DWR 70 t | V 013 257 .B06 |

| Spare Part: 15 m connect- ing cable with

plug socket |

V 023 643 .B01 |

상품평

아직 상품평이 없습니다.